Search the whole station

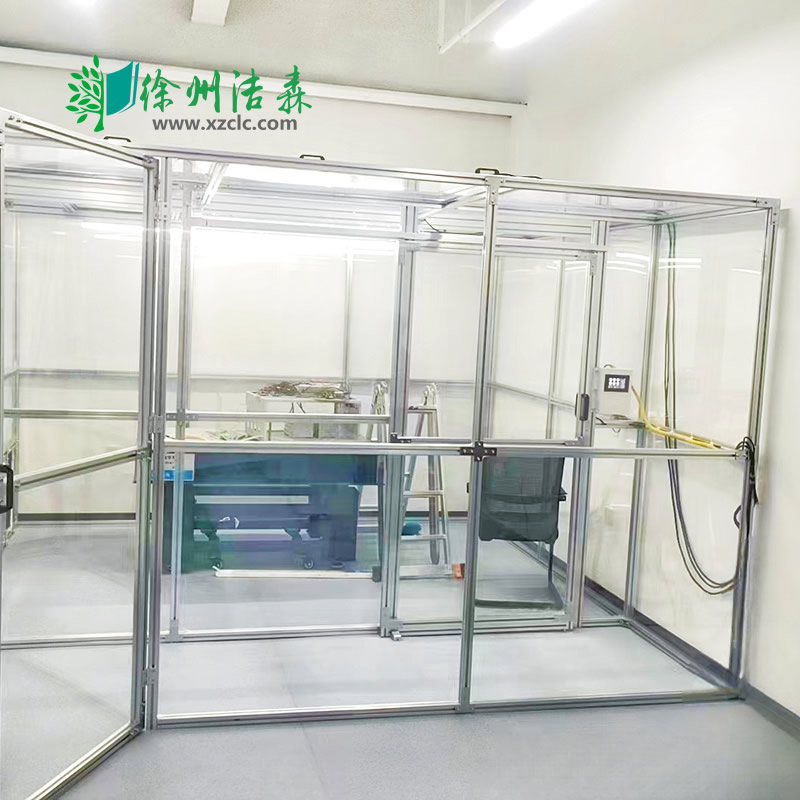

Class 10000 clean room is a simple clean room that can be quickly and conveniently established. It is made of industrial aluminum (or stainless steel, cold plate square tube) as the frame, equipped with a built-in fan filter unit (FFU) for air supply, and surrounded by anti-static soft curtains (or acrylic sheets). The internal purification level can reach hundreds to hundreds of thousands.

Before understanding the concept of a Class 10000 cleanroom, let’s first understand the key points of knowledge about the cleanliness of a Class 10000 cleanroom. A Class 10000 cleanroom, also known as a Class 10000 cleanroom or a Class 10000 dust-free workspace.

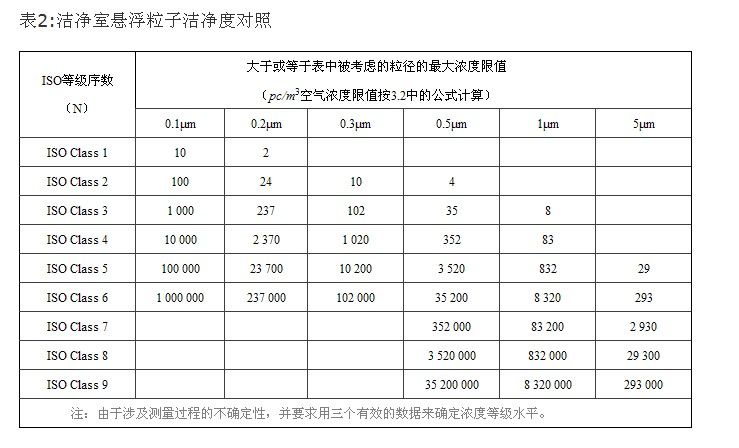

Cleanliness of Class 10000 cleanroom:

Cleanliness refers to the degree of dust particles in the air in a clean environment. According to the national standard GBJ73-84 of the People’s Republic of China, the “Code for Design of Cleanrooms” (hereinafter referred to as the “Code”) specifies different levels of air cleanliness (cleanliness refers to the degree of dust particles in the air in a clean environment), and corresponding tables are made to indicate the classification standards:

Cleanliness parameter table for Class 10000 cleanrooms

Note: Therefore, the 10000 level mentioned earlier means that there are currently less than 3500000 dust particles with a particle size of 0.5 nanometers per cubic meter of air, and less than 20000 dust particles with a particle size of 5 nanometers per cubic meter of air. There are also less than 500 planktonic bacteria and 10 sedimented bacteria per cubic meter of air.

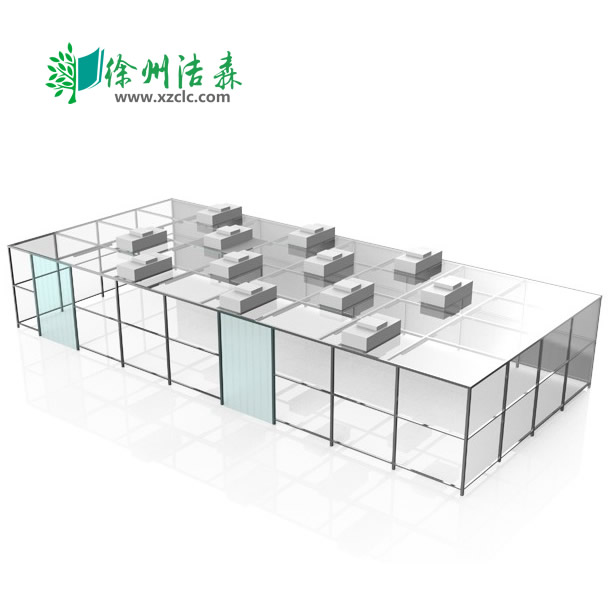

The Class 10000 cleanroom is suitable for local areas in the workshop that require high cleanliness, such as assembly line operation areas and high-precision product assembly areas.

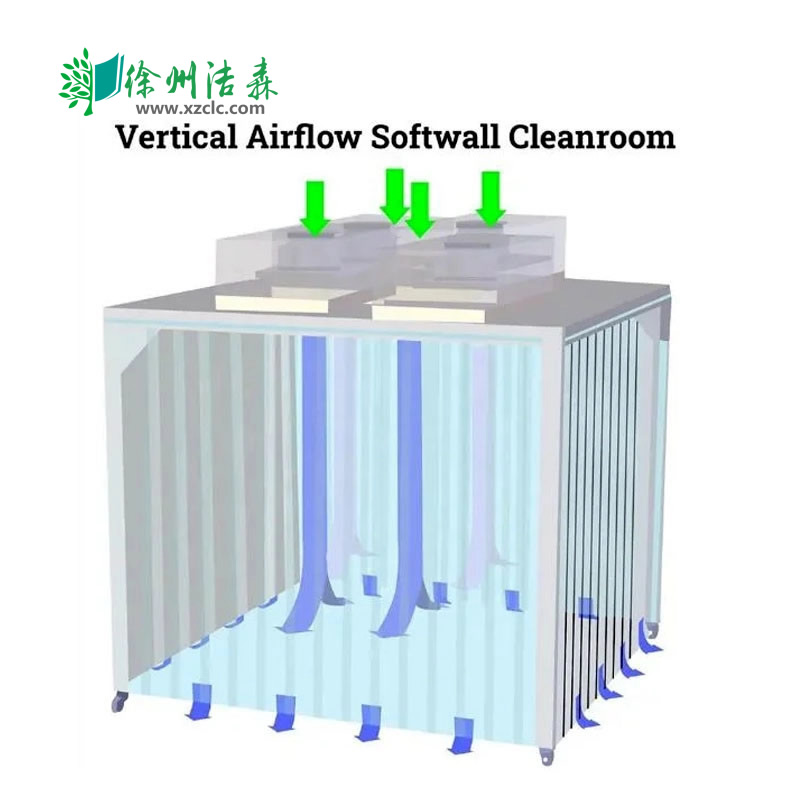

Working principle of 10000 level clean room:

The fan sucks in air from the top of the FFU, and after initial and efficient filtration, the filtered clean air is uniformly sent to the clean room on the outlet surface, forming a uniform flow layer. The airflow is unidirectional, ensuring the required cleanliness and safety in the work area.

Product configuration for Class 10000 cleanroom:

1. Specification: This product has no standardized specifications and is made entirely according to the customer’s needs

2. Frame: Aluminum profile (stable, beautiful, rust free, dust-free)

3. Electrostatic Curtain: 0.5mmT Grid (Good anti-static effect, high transparency, clear grid, good flexibility, no deformation, not easy to age, dustproof and anti-static)

4. The top cover of the clean shed can be made of 3mmT aluminum-plastic panel

5. Partial use of purification room specific purification lamps

6. Filter unit FFU: using AC AC centrifugal fan with specifications of 1175 * 575 * 350mm, with an initial high-efficiency two-stage filtration system, filtration efficiency of 99.99% (0.3um), adjustable wind speed, maximum air volume: 1200m3/h); Featuring long lifespan, low noise, maintenance free, minimal vibration, and infinitely variable speed, the fan is reliable in quality and has a long working life. Coupled with a unique air duct design, it greatly improves the efficiency of the fan and reduces noise

7. FFU fan filter units are arranged at intervals on the top to achieve a purification level of 10000.

Product characteristics of Class 10000 cleanroom:

*Modular design, easy to install, greatly shortens the delivery cycle;

*Easy to move, can install silent universal wheels;

*Suitable for building small clean areas;

*Modular structure, easy to improve purification level, strong scalability, and high reuse value;

*Compared to ultra clean workbenches, there is a large available effective space inside;

*Compared to traditional clean rooms, it has lower costs, faster construction, and no restrictions on floor height.

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.