Cleanroom Work Standards and Regulations

Cleanroom Work Standards and Regulations

1. Only necessary personnel are allowed in the clean room. The more people indoors, the higher the pollution level.

2. Only trained personnel are allowed to work in the clean room, and only those with specific skills required for the job are allowed to enter the clean room.

3. No staff is allowed to bring anything that may cause pollution into the clean room. Only items necessary for working in the cleanroom can be brought in. And when preparing these items, anti pollution measures should be taken.

The following items are not allowed in the clean room:

a: Food, beverages, candies, chewing gum

b: Cigarettes, pipes, snuff

b: Radio, turntable, pocket recorder

c: Items made of wood, rubber, paper, leather, cotton, and other natural materials

d: Non cleanroom specific paper, including newspapers, magazines, books, and tissues

e: Lead pencils and erasers

f: Writing supplies that can release particles, such as fiber pens

4. It is necessary to close the door casually. Opening the door will reduce the indoor pressure, which will cause poor airflow in the clean room.

5. The action of opening and closing the door should be slow, as quickly opening and closing the door will increase the amount of air flowing into the clean room from areas with lower cleanliness. To control the speed of opening and closing the door, a door closer or spring can be installed on the door.

6. The cleanroom should always be kept clean and tidy. Regularly replace high-efficiency filters, and an irregular clean room will never be clean.

7. Compared to the production process, personnel should be in the correct position. For example, leaning against the product is a bad habit because it can cause “dead” particles and microbial particles on the cleanroom to fall onto the product and its surroundings. Personnel working in unidirectional flow should not sit directly in the unidirectional flow, as this will cause the airflow to blow loose particles from clothing into the air. Careful planning of the working methods used in the clean room is necessary to minimize the risk of contamination.

8. When moving items in the clean room, do not let them come into contact with clothing or other items.

9. When working near the product, avoid speaking. Even with a face mask, particles emitted from the nose and mouth remain a clean source of pollution.

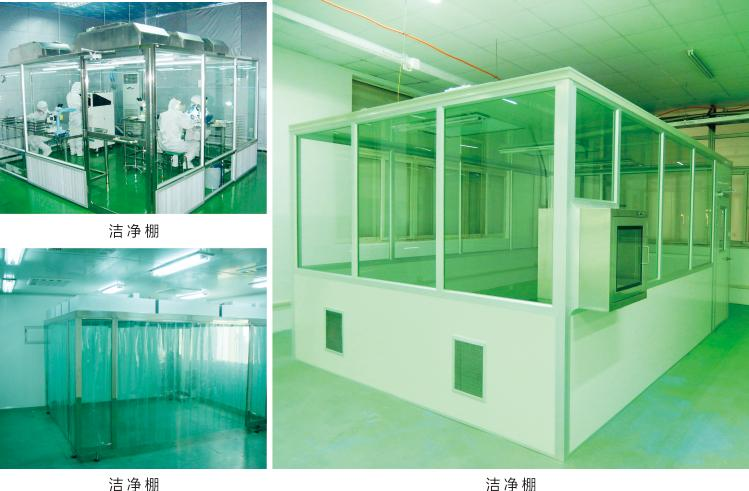

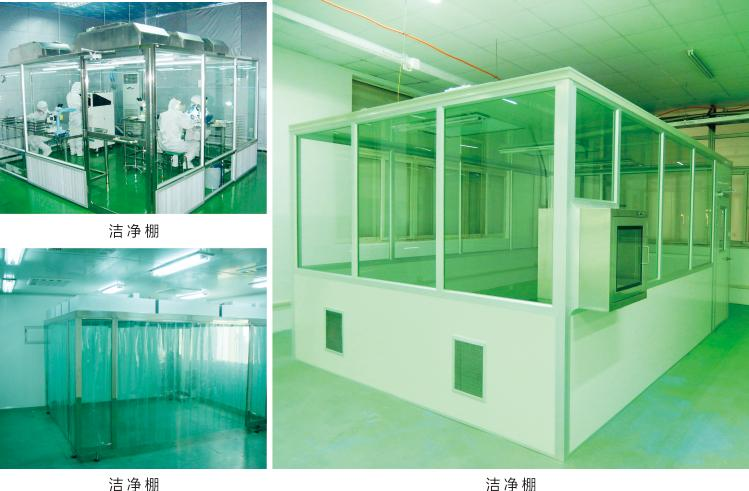

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

" width="300" height="300" alt="Modular cleanroom designs" />

" width="300" height="300" alt="Modular cleanroom designs" /> " width="300" height="300" alt="Classification Impacts For Cleanroom" />

" width="300" height="300" alt="Classification Impacts For Cleanroom" /> " width="300" height="300" alt="Modular Cleanrooms Facts" />

" width="300" height="300" alt="Modular Cleanrooms Facts" /> " width="300" height="300" alt="Cleanroom HVAC Designs" />

" width="300" height="300" alt="Cleanroom HVAC Designs" />

HelloPlease leave a message