Search the whole station

Grade 10 cleanroom | Characteristics of Grade 10 cleanroom:

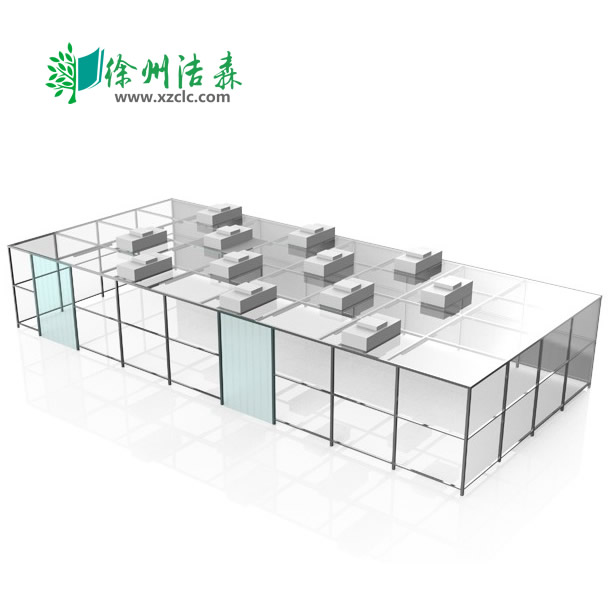

① Grade 10 cleanrooms can be used individually or in combination.

② Compared with civil or prefabricated Class 100 cleanrooms, Class 10 cleanrooms have lower investment, faster results, easier installation, and lower operating costs.

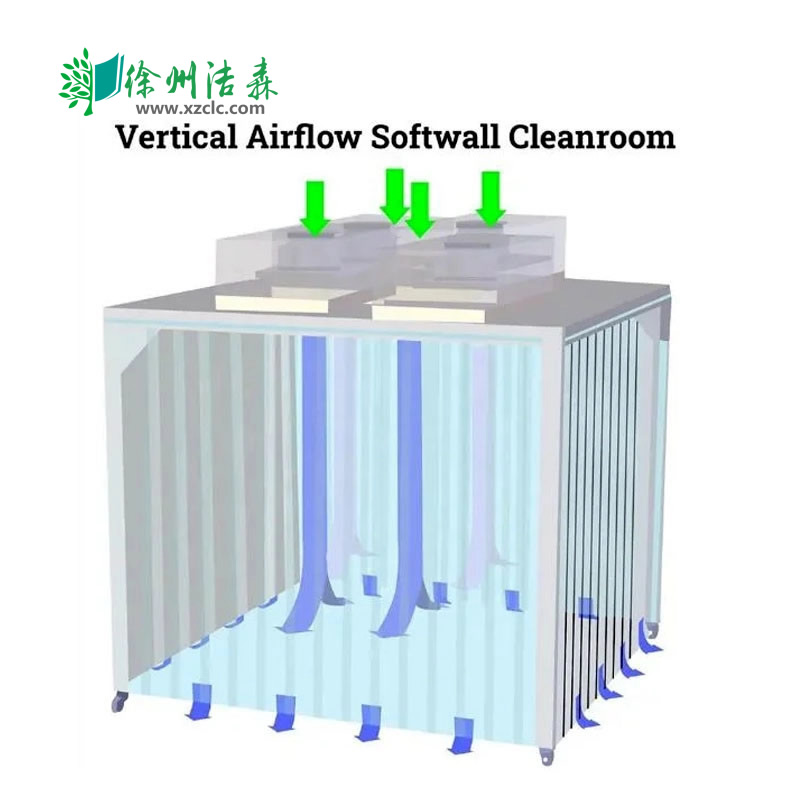

Level 10 cleanroom | Principle of Level 10 cleanroom:

The fan sucks in air from the top of the FFU, passes through a primary filter and an ultra high efficiency filter, and the filtered clean air is uniformly sent out to the cleanroom at a speed of 0.45m/+20% on the entire air outlet surface. Forming a uniform flow layer ensures a vertical unidirectional flow of clean air, thereby guaranteeing the required cleanliness within the workspace.

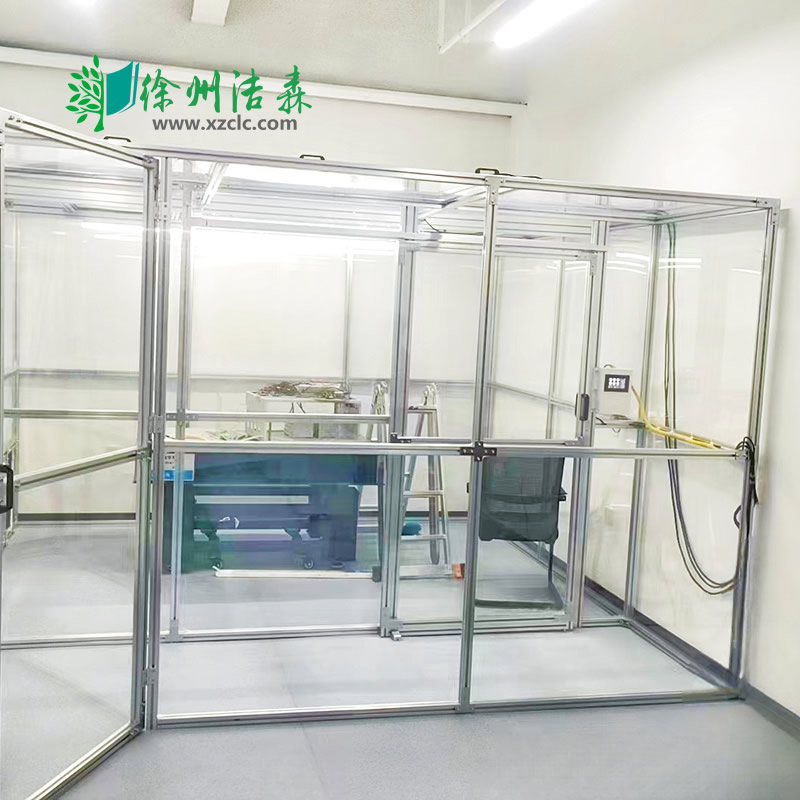

Grade 10 cleanroom | Material configuration for Grade 10 cleanroom

1. Specification: This product has no standardized specifications and is made entirely according to the customer’s needs

2. Framework: 50 * 50 spray painted steel square tube (stable, beautiful, rust free, dust-free) or aluminum profile and stainless steel, etc

3. Electrostatic curtain: 0.5mm mesh (with good anti-static effect, high transparency, clear mesh, good flexibility, no deformation, not easy to age; dustproof and anti-static)

4. The roof cover plate is made of 1.2mm cold-rolled steel plate with electrostatic spraying or organic glass.

5. Partial use of purification room specific purification lamps.

6. Filter unit FFU: using AC EBM355 centrifugal fan, size specification 1175 * 1175 * 350mm, dual stage ultra high efficiency filter system, filtration efficiency 99.9999% (0.12um), adjustable wind speed, maximum air volume: 1200m3/min), (with characteristics of long life, low noise, maintenance free, low vibration, and stepless variable speed, the fan quality is reliable, the working life is long, and the unique air duct design greatly improves the efficiency of the fan and reduces noise)

7. The top is covered with FFU fan filter units to achieve a ten level purification level.

This product can be made according to the specific needs of customers, such as material, size, etc.

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.