Search the whole station

The cleanliness level of a cleanroom is classified based on the concentration of particulate matter in the internal air. A level 10 cleanroom represents extremely high cleanliness requirements and is suitable for occasions with special requirements for environmental cleanliness.

Principle of Level 10 Clean Room

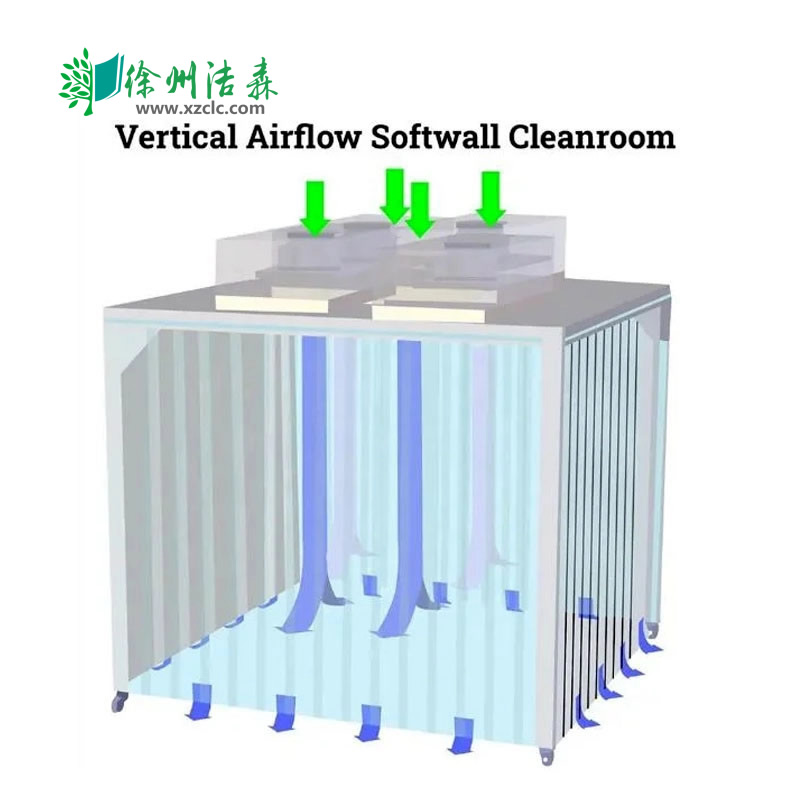

The fan sucks in air from the top of the FFU, and after passing through the primary and high-efficiency filters, the filtered clean air is uniformly sent out to the cleanroom at a speed of 0.45m/s ± 20% on the entire air outlet surface. Form a uniform flow layer to ensure a vertical unidirectional flow of clean air, thereby guaranteeing the required cleanliness in the work area.

Construction of Level 10 Cleanroom

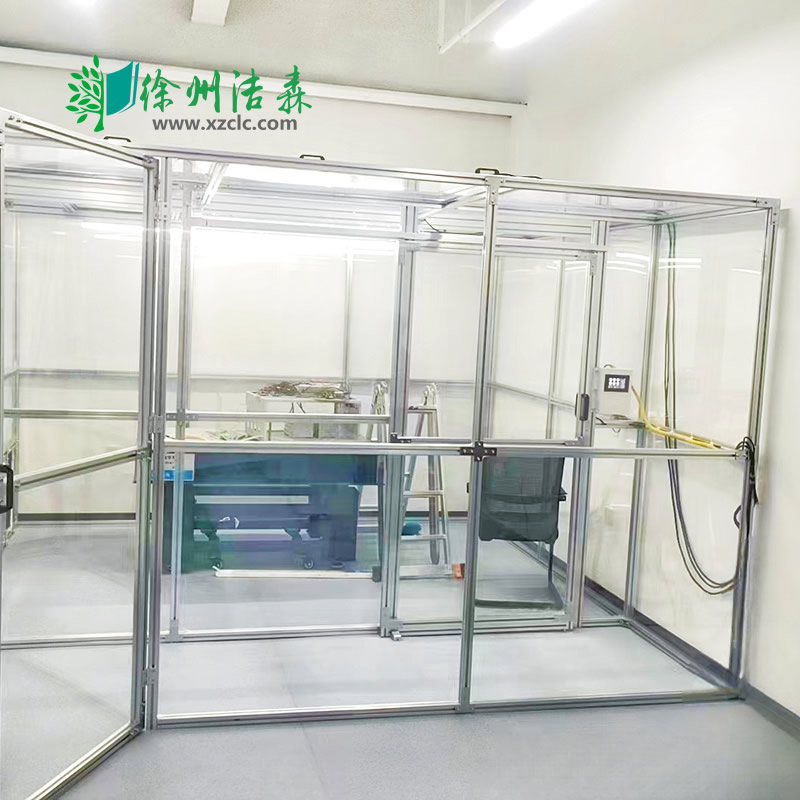

Framework: Made of industrial aluminum (or stainless steel square tube, iron square tube spray), it has the characteristics of stability, beauty, no rust, and no dust production.

Anti static curtains: Anti static curtains (or tempered glass) are used around the perimeter, which have good anti-static effect, high transparency, clear grid, good flexibility, and are not easily deformed or aged.

Fan filter unit FFU: using centrifugal fan, it has the characteristics of long life, low noise, maintenance free, low vibration, and stepless speed change. The internal purification level can reach 100-100K level; Especially suitable for areas with high local purification requirements in the workshop.

Purification lamp: The interior adopts a dedicated purification lamp for the purification room, which will not produce dust.

Level 10 cleanroom application areas: widely used in electronics, microelectronics, precision instruments, biomedicine, food processing, aerospace and many other fields.

Advantages of Level 10 Cleanroom

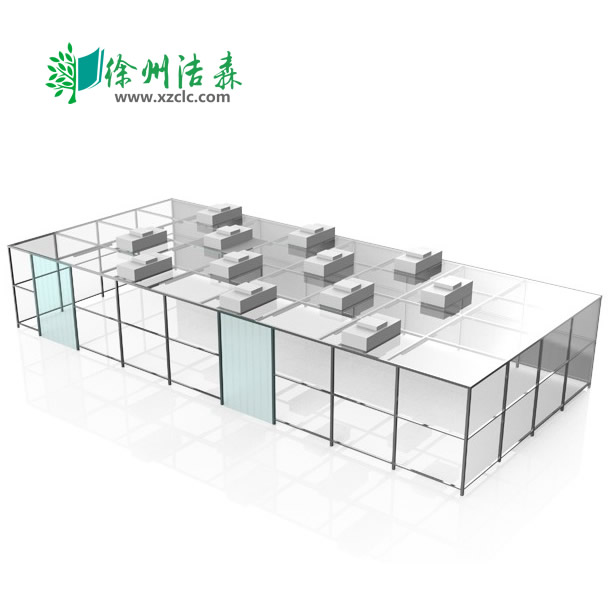

It can be used alone or in combination.

Compared with traditional civil or prefabricated cleanrooms, it has lower investment, faster results, easier installation, and lower operating costs.

Modular structure, easy to improve cleanliness level, strong scalability, and high reuse value.

Easy to move (universal wheels can be installed).

Grade 10 cleanroom manufacturer

Xuzhou Jiesen Environmental Protection Technology Co., Ltd. is a professional manufacturer engaged in the design and processing of 10 level clean sheds. It has been established for many years and has customers all over the country. Its products are widely praised and it is a senior factory. Welcome to consult! Negotiate cooperation!

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.