Search the whole station

|

FFU:

|

1175*575*300mm Multiple

|

Material:

|

SS304 Frame Or Aluminum Square

|

|

Purification Levels:

|

Class 100-100000

|

Specification:

|

Customized

|

|

Wall::

|

Acrylic Sheet Or Toughened Glass

|

Packaging:

|

Wooden Case

|

|

Terms:

|

CIF/EXW/FOB

|

Delivery Time:

|

7-15days

|

|

Application:

|

Pharmaceutical / Microelectron / Photoelectric / Food Productiion

|

Installation:

|

On-site Installation Or Installation Manual Online Instruction

|

Modular Clean Room Descripition:

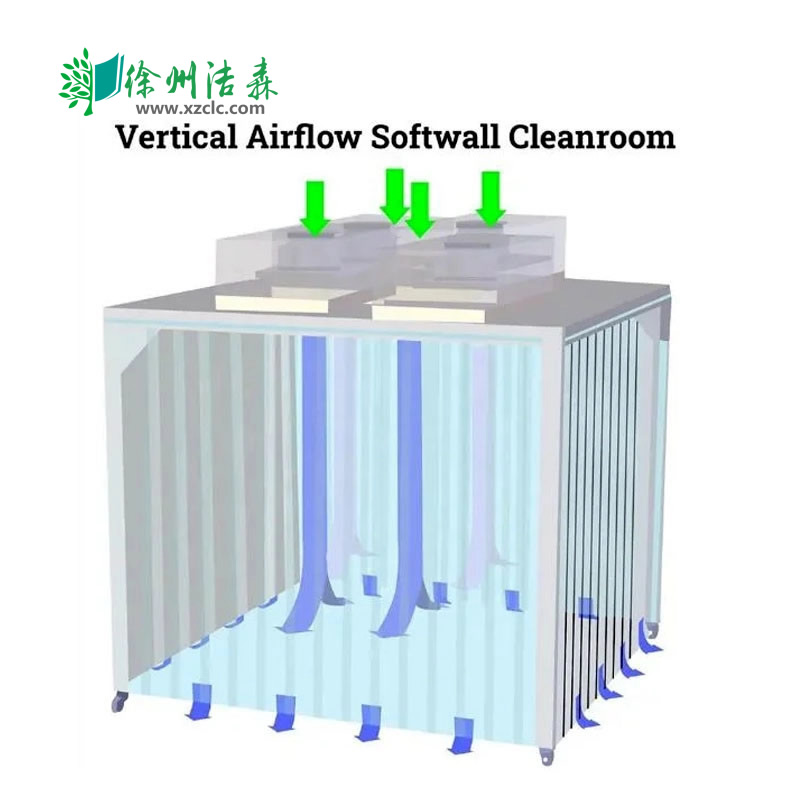

With FFU(fan filter unit)as the core,clean booth provides a high level cleanliness.which draws in contaminated air from the top of the module,and exhausts filter clean air vertically in a unidicetional(Laminar) air stream at its base.is a self-contained fan and filter module for clean room applications.

It is a good option to create a cleaner space within an existing normal room or a room with low-level of cleanliness.

If you do the following, I believe that you can effectively extend the life of the clean room.

1, temperature and humidity. The temperature and humidity of the clean booth are usually controlled in the case of a change in the control value or in a range of 10%.

2, energy saving. Produced in a clean shed, the unit consumes a lot of energy, which is mainly caused by the large power consumption of the air-conditioning system. In the air-conditioning system of the clean booth, the high-efficiency filter, medium-efficiency filter, and effect filter follow the prolonged operation time, and the amount of dust adsorbed on the filter gradually increases, causing the pressure loss to increase and the air volume to decrease. Therefore, the primary filter must be replaced and cleaned frequently.

3, entrants handling and teaching. Since the first factor that may affect cleanliness is dust, the workers entering the clean shed must be healthy in their mental state and physical condition, and they must be instructed to improve their cleanliness. Responsibility for working in the shed. What is more important is to deepen the substantive understanding of the clean shed itself.

4, the handling of clean clothes. As mentioned earlier, clean work clothes must be worn when entering a clean shed. From the perspective of no dusting, most of them are full-blown cleansing clothes made of polyester fibers. However, with the extension of the use of time, the dust emission of such a full-scale clean suit will increase, so regular cleaning must be performed.

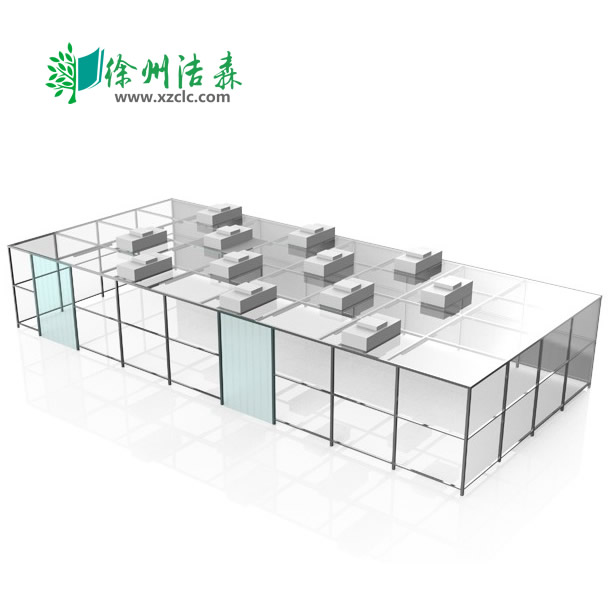

Our regular size of clean room Parameter

| Parameter | Softwall Clean Booth(PVC) | Hardwall Clean Booth(Toughened glass,color steel panel) | ||

| Cleanliness | From Class 100 to Class 100,000 | |||

| External Dimension | As per requirement | |||

| FFU | Dimension | 2*2/2*4/4*4 | ||

| Cabinet Material | Stainless Steel | |||

| Power source | 110V/60hz/av/dc, 220V/60HZ/AV/DC | |||

| HEPA Filter | H14 Hepa filter | |||

| Frame Material | Stainless Steel | |||

| Wall Material | Anti-static soft PVC wall 106~109Ω | Anti-static acrylic 106~109Ω | ||

| Lighting | Lamps | Available in LED and T5 | ||

| Air condition | As per requirement | Available in constant temperature air conditioner/constant temperature and humidity conditioner | ||

| Class Level | Model | Inner dimension | Number of | Air volume(m3/h) |

| W * D * H (mm) | FFU | |||

| Class100 | ALCS6 * 8 | 2000 * 3000 * 2200 | 6 | 6600 |

| ALCS 8 * 12 | 2440 * 3660 * 2200 | 12 | 13200 | |

| ALCS 8 * 16 | 2450 * 4880 * 2200 | 16 | 17600 | |

| ALCS 8 * 20 | 2440 * 6100 * 2200 | 20 | 22000 | |

| Class 1000 | ALCS6 * 8 | 2000 * 3000 * 2200 | 2 | 2200 |

| ALCS 8 * 16 | 2440 * 4880 * 2200 | 4 | 4400 | |

| ALCS 12 * 16 | 3660 * 4880 * 2200 | 6 | 6600 | |

| ALCS 20 * 24 | 6100 * 7300 * 2200 | 12 | 13200 | |

| Class 10000 | ALCS6 * 8 | 2000 * 3000 * 2200 | 1 | 1100 |

| ALCS 8 * 16 | 2440 * 4880 * 2200 | 2 | 2200 | |

| ALCS 12 * 16 | 3660 * 4880 * 2200 | 4 | 4400 | |

| ALCS 20 * 24 | 6100 * 7300 * 2200 | 8 | 8800 | |

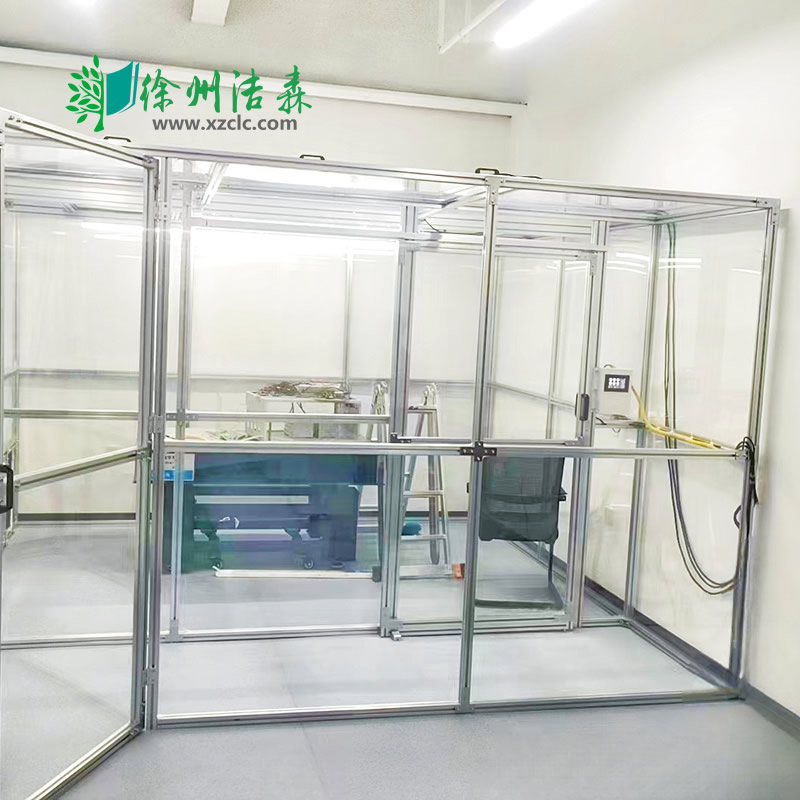

Hardwall modular cleanroom offer a completely enclosed, rigid cleanroom option with vents to exhaust air. Hardwall cleanrooms can maintain pressure differentials, which may be required to meet certain standards for cleanliness.

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.