1、 Definition of Clean Room

A clean room refers to a specially designed room that removes pollutants such as particles, harmful air, and bacteria from the air within a certain spatial range, and controls the indoor temperature, cleanliness, indoor pressure, airflow velocity and distribution, noise vibration, lighting, and static electricity within a certain required range. That is to say, regardless of changes in external air conditions, the indoor environment can maintain the originally set requirements for cleanliness, temperature, humidity, and pressure.

Compared to dust-free workshops and purification plants, clean rooms have much smaller volume sizes and usually refer to purification projects for individual rooms. Clean rooms are a widely used project in air dust-free purification engineering.

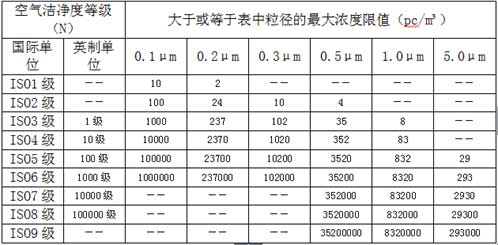

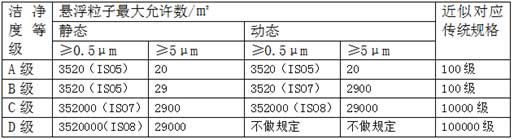

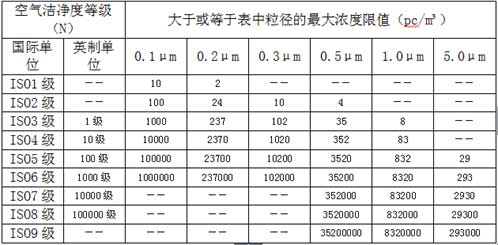

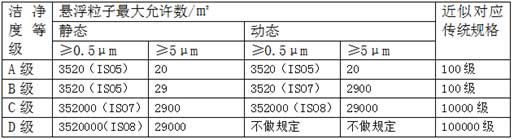

2、 Cleanroom level

Table of integer levels of air cleanliness in clean rooms and clean areas:

New version of pharmaceutical GMP cleanliness level ABCD air suspension particle standard:

3、 Components of a cleanroom

The composition of a clean room is composed of the following systems (all of which are indispensable in the system molecules), otherwise a complete and high-quality clean room cannot be constructed.

Enclosure construction refers to the sealed space that constitutes a clean room. Including: 1) Ceiling system: including suspension rods, steel beams, and ceiling grid beams. 2) Partition board: including windows and doors. 3) Flooring: including elevated flooring, anti-static board, epoxy self leveling, PVC purification flooring, etc. 4) Indoor channel accessories: including air shower rooms, changing rooms, transfer windows, etc

Air conditioning and purification system, including: 1) purification unit, 2) filter system, 3) piping system: air ducts, water pipes, copper pipes, etc

Intelligent control system, including: 1) lighting and lighting control, 2) intelligent and remote control system

4、 Cleanroom classification

Cleanrooms are mainly divided into industrial cleanrooms (dust-free) and biological cleanrooms (dust-free, sterile)

Industrial cleanrooms and biological cleanrooms are actually both classified as cleanrooms, with the fundamental difference being that they are designed for dust-free and sterile purposes. Therefore, there should be a focus on their design and construction.

Industrial cleanrooms are suitable for various industries such as fine machinery, electronics (semiconductors, integrated circuits, etc.), aerospace, high-purity chemical, atomic energy, optomagnetic products (optical discs, films, magnetic tape consumption), LCD (liquid crystal glass), computer hard drives, computer magnetic head consumption, etc.

Biological cleanrooms are suitable for the pharmaceutical industry, hospitals (operating rooms, sterile wards), food, cosmetics, beverage product consumption, animal laboratories, physical and chemical testing rooms, blood stations, etc.

5、 Construction of cleanroom

The construction of a clean room is mainly to maintain tightness and cleanliness.

1. Main structure of clean room

The main structure of a construction clean room is generally a reinforced concrete structure, surrounded by brick walls. This process is the outermost layer of the clean room’s clean barrier. During construction, attention should be paid to:

1) The holes in concrete and brick walls should be repaired to reduce wall cracks;

2) Measures should be taken to prevent cracking at the connection between concrete and brick walls;

3) The plastering of interior and exterior walls should be carried out in layers to prevent wall cracks and hollowing, especially for interior walls. It is often thought that there are clean wall panels inside and plastering is not necessary, but this is a wrong idea. This layer of plastering is very important. Cleanroom decoration projects can greatly help with later cleaning, reducing dust and noise by about 10%.

2. Clean board wall construction

Nowadays, most clean rooms are installed using a combination of clean panels. During construction, attention should be paid to:

1) Before construction, it is necessary to first complete the dimensions according to the structure on site and draw the wall panel construction layout plan. Nowadays, many companies draw the wall panel layout plan according to the construction drawings during construction, which has a significant difference in size from the site, making the drawn construction layout plan useless. The construction arrangement diagram can reduce the joints of the wall panels in advance, greatly reducing dust and other debris, and improving cleanliness;

2) The connecting strips between clean wall panels cannot be omitted. If they are omitted, it will be useless to apply glue at the joints in the future. As time goes by, the wall panels will be staggered and the glue will crack;

3) Do not tear off the protective film of the clean board, wait until the floor and ceiling are finished before tearing it off;

4) The joints of the clean board should be tight, tightly pressed against each other, and not movable;

5) During the construction of clean wall panels, the dust in the gaps between the wall panels, concrete, and brick walls must be cleaned with a vacuum cleaner. At the same time, the dust, garbage, and other debris on the walls, floors, and ceilings must be cleaned up;

6) The door of the clean room must be airtight and have good sealing performance to ensure the isolation of air and sound inside and outside the door.

3. Construction of Clean Board Ceiling

The ceiling system is one of the basic systems of a clean room. The ceiling used in this project is a clean panel ceiling. During the construction of the clean room decoration project, attention should be paid to:

1) Like wall panel construction, before construction, a ceiling arrangement diagram should be drawn based on the actual structural dimensions on site, with the same purpose as the wall panel;

2) Due to the need for manual maintenance on the ceiling, the clean panel must have sufficient strength and rigidity to ensure that it does not deform, crack, or form adhesive joints after being installed on the ceiling;

3) The joints between air conditioning fresh air, lighting fixtures, etc. and the ceiling should be tight and tightly pressed against each other.

4. Construction ground of ground system

Generally, epoxy resin flooring, elevated flooring, etc. are used. In this project, epoxy resin self leveling flooring is used. During construction, attention should be paid to:

1) The concrete base should be flat and firm, and cracks should be repaired in advance to ensure that there are no cracks after the epoxy resin paint is completed;

2) Epoxy materials must meet the design requirements;

3) The grassroots should be polished flat, and dust should be sucked clean with a vacuum cleaner while polishing;

4) After the epoxy resin floor is completed, a clean vacuum cleaner must be used for vacuuming, and ordinary vacuum cleaners cannot be used.

5. Clean room decoration project gluing

Gluing is the final process, and the quality of gluing directly affects the cleanliness of the clean room. When gluing, attention should be paid to:

1) The materials must meet the requirements;

2) The glue should be applied to every area without any omissions. The location where the glue needs to be applied is the ceiling joint; Wall panel joints; The junction of different materials; Seam between ceiling and wall panels; Wall panel and ground joint; Seam between lighting fixtures and ceiling; Joints between air vents and ceilings, etc;

3) In order to prevent the material adhesive from reacting with epoxy paint and causing the adhesive to change color, the adhesive should be applied after the epoxy paint floor is completed.

6. Overall requirements for clean room decoration engineering construction

1) All materials brought into the cleanroom must be thoroughly cleaned;

2) The pipeline well connected to the clean room must be cleaned with a clean vacuum cleaner;

3) When entering the clean room, it is necessary to wear clean clothes that meet the requirements, preferably full face nylon clean clothes, and cotton clean clothes are prohibited;

4) During the construction period, the air shower room should be installed in advance, and entering the clean room must pass through the air shower room;

5) Clean room dust-free cloth should be used when cleaning the walls in the cleanroom;

6) The floor of the clean room should be cleaned with a dedicated mop;

7) When working, always remember to wipe from top to bottom, from the farthest point away from the door towards the direction of the door.

To ensure the success of clean room civil construction, the following principles should be followed: strictly control the procurement and use of materials, and ensure the dust-free inspection of each process; Design a reasonable construction action plan; Strengthen the technical and quality education of construction personnel; Prepare all kinds of tools and equipment.

Xuzhou Jiesen has a professional clean room design team (including decoration, HVAC, gas circuit, purification, electrical, control, etc.) with rich construction experience. Welcome to inquire!

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

" width="300" height="300" alt="Modular cleanroom designs" />

" width="300" height="300" alt="Modular cleanroom designs" /> " width="300" height="300" alt="Classification Impacts For Cleanroom" />

" width="300" height="300" alt="Classification Impacts For Cleanroom" /> " width="300" height="300" alt="Modular Cleanrooms Facts" />

" width="300" height="300" alt="Modular Cleanrooms Facts" /> " width="300" height="300" alt="Cleanroom HVAC Designs" />

" width="300" height="300" alt="Cleanroom HVAC Designs" />

HelloPlease leave a message