Search the whole station

|

Material:

|

80*80powder Coating

|

Purification Levels:

|

ISO 8

|

|

Standard:

|

ISO90001

|

Wall:

|

Pvc Grid Curtain

|

|

FFU Power:

|

170w

|

Terms:

|

CIF/EXW/FOB

|

|

Delivery Time:

|

7-15days

|

Export Desitination:

|

Canada

|

|

Package:

|

Plywooden Case

|

Clean room is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contaimination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5um and larger in diameter, corresponding to an ISO9 cleanroom, while an ISO1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3um and smal

We made 1000+clean rooms for different pharm companies since we built factory from 2001, if you are a pharm company, I think you need a clean room for Liquid filling of capsules, because clean room can keep partial cleaning where need high air quality for your production. Now we are just making a drawing for another pharma company which is located in Ontario, Canada after they confirmed us as their supplier. Here drawing is for your review and welcome to send us your requirements, we will design it for you based on your requirement

s!!

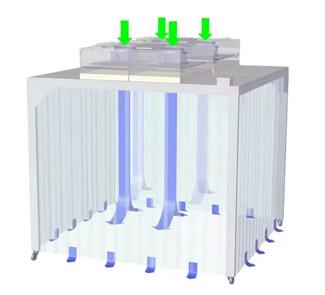

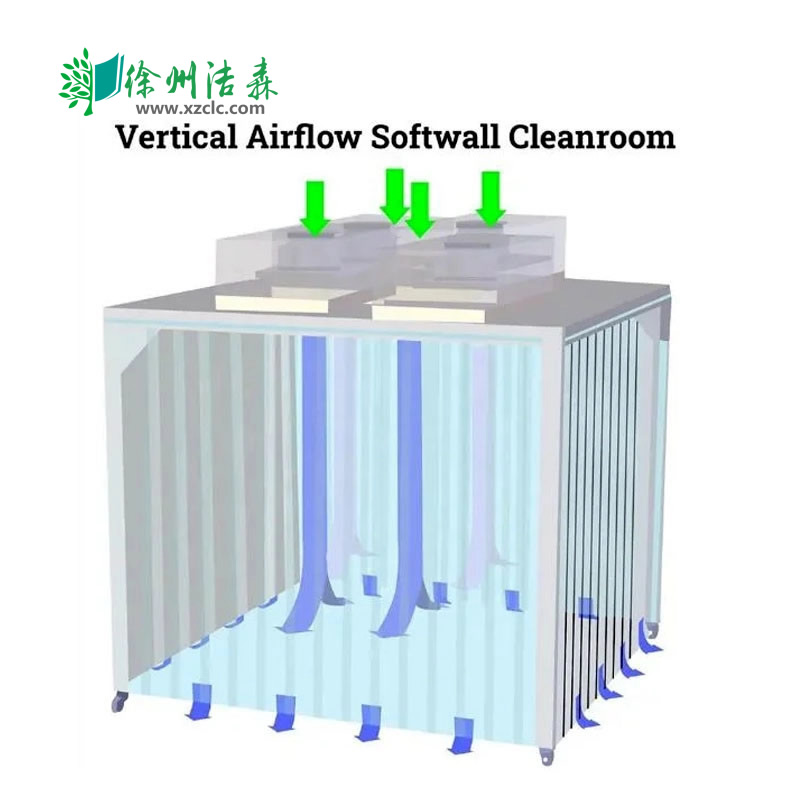

Features:

(1) Assembly structure designed, easy installation and shortening the delivery time;

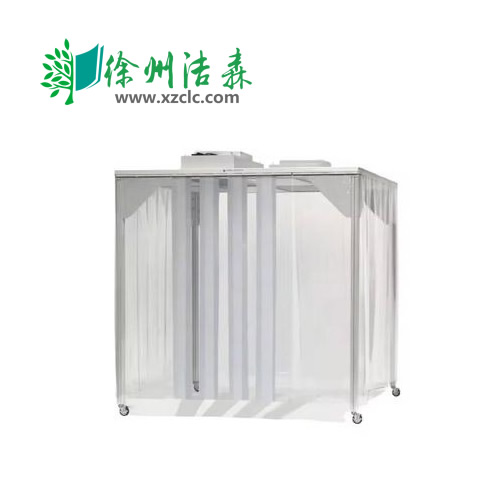

(2) Easily moved (Omnidirectional wheels can be installed), suitable for building small and high cleanliness area;

(3) Module structure to improve high cleanliness class easily, great expansibility and high value for reusing;

(4) Compared with ultra-clean clean bench, clean booth has large useful and effective area; while compared with traditional clean room, it has such features as low cost, fast construction and no limits for low floor.

3. Materials for Clean Room

(1) Frame: Aluminum profile 40*40/40*80mm used in industry, which is firm, beautiful, rustless and no dust attached;

(2) Anti-static curtain: the thickness of grid: 0.5mm; effectively anti-static, great transparent, clear grid, soft, good toughness, no deformation, not getting burnt-in easily and great performance in temperature compartment and, dust and static elimination;

(3) Coverd in the top by purification blind plate, the thickness of which is 1.2mm of plastic spraying cold plate;

(4) Purification lighting system is used inside of the clean booth;

(5) Air supply unit FFU: adopting low noise centrifugal fan, with such features as long service life, low noise, maintenance free, low vibration and adjustable speed. And in the end of FFU is Mini-pleat HEPA Filters, which is low initial resistance, high dust holding capacity, high efficiency, long service life, easy replacement and etc…

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

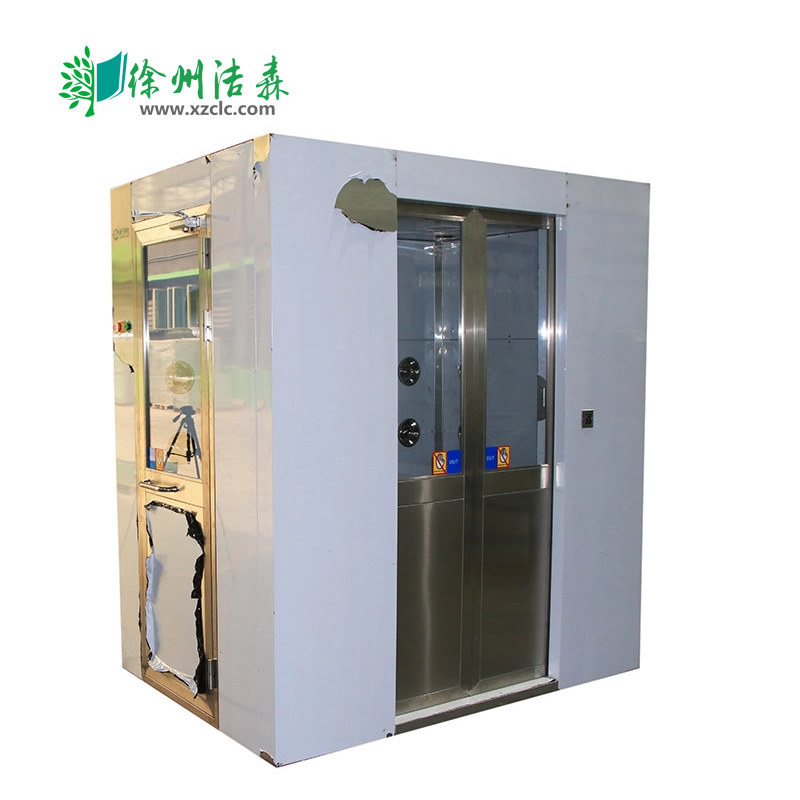

Highlight: l shaped air shower clean room, pharmaceutical industry air shower clean room, custom a……

Highlight: cleanroom air shower, purifying cleanroom air shower, 316 stainless steel air shower ……

Highlight: Automatic Induction Cleanroom Air Shower, SUS304 Cleanroom Air Shower, 27m/S Automatic ……

Highlight: prefabricated modular operating room, modular operating room clean room project, prefab……

Highlight: customized double leaf swing door, clean room double leaf swing door, cleanroom double ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.