Structural principle, classification and application of special air purification equipment air shower room

Designers in the purification industry know that in clean rooms, the layout of pedestrian and logistics channels is extremely strict, and people and objects entering and leaving the clean room must follow relevant procedures. This involves the main content of our article: air shower room.

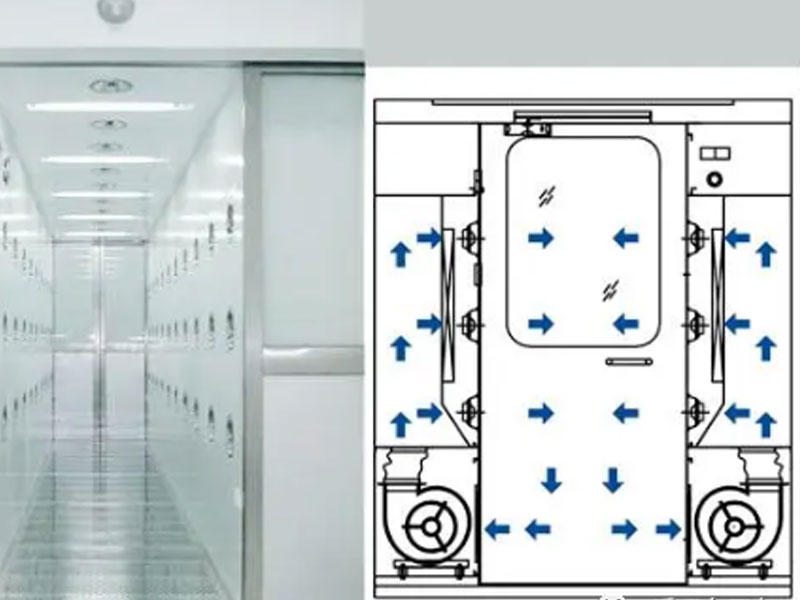

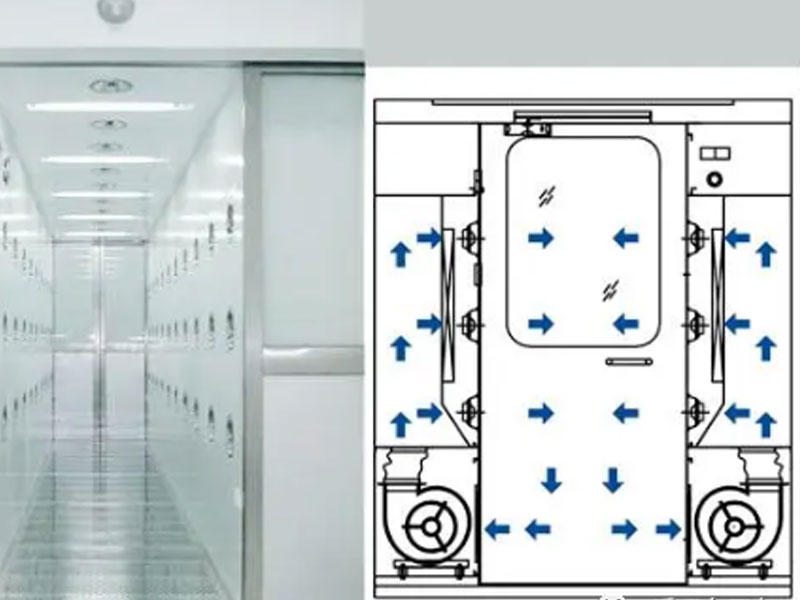

In purification engineering, air showers need to be installed on the flow channels of certain clean rooms. When people pass through the air shower, the high-speed clean airflow can blow away dust particles on the clean work clothes to prevent dust from contaminating the clean room.

Friends who have worked on clean room projects in the electronics industry should have noticed that there are many air shower rooms used in clean rooms in the electronics industry. With the development of the times, many electronic industry cleanrooms now not only set up air shower rooms in pedestrian flow channels, but also use air shower rooms in large logistics channels to purify dust particles attached to the logistics surface, in order to ensure the cleanliness of the cleanroom.

The structural principle and classification of air shower rooms

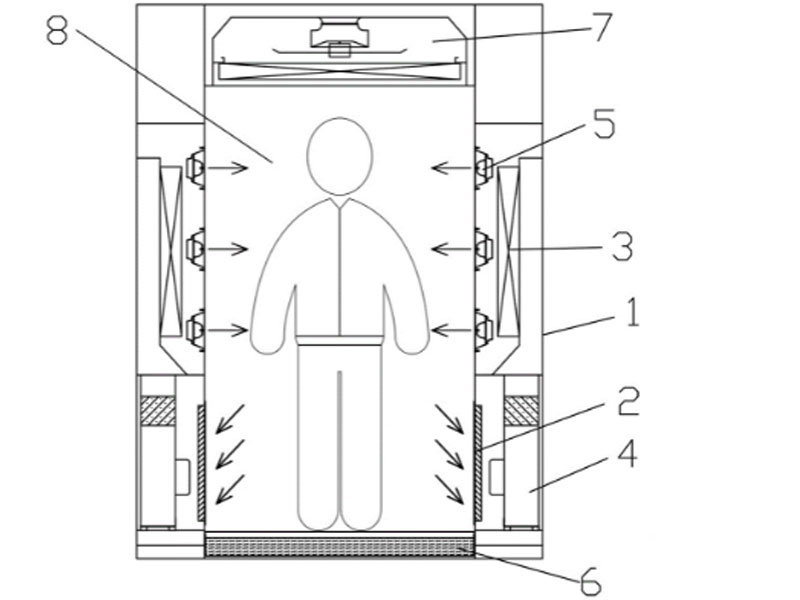

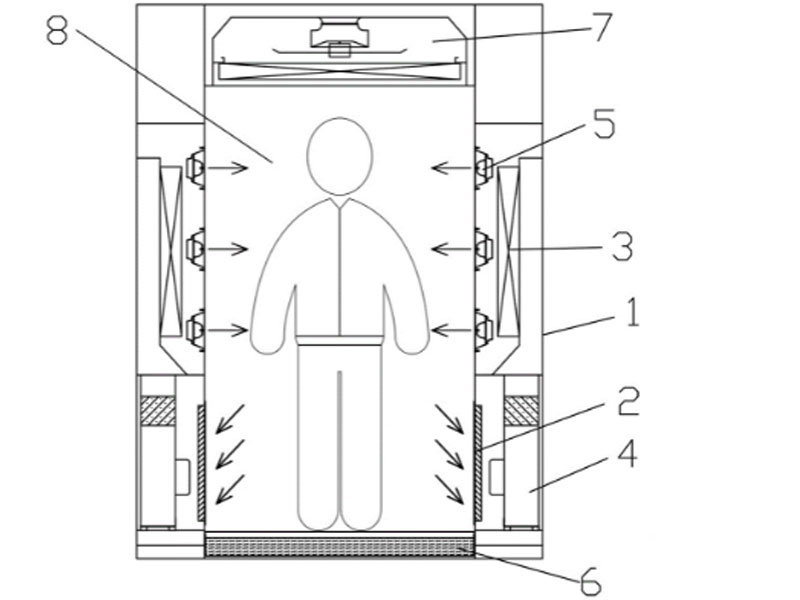

The air shower room, also known as the air blowing shower room, is mainly composed of fans, filters, nozzles, interlocking doors, and control systems.

The principle is that the clean air filtered by the high-efficiency filter is sprayed out from the nozzle on the wall of the air shower room, blowing off the dust on the work clothes. The dusty air is sucked in by the fan through the coarse (primary) filter, pressurized, and flows through the high-efficiency filter before being sprayed out from the nozzle. This cycle forms an internal circulation and filtering air purification device.

In general, the control system of the air shower room is as follows: the air shower room will be equipped with a timing device. When the staff enters the air shower room, they can press the start button to enter the time for closing the door and blowing. Generally, the air shower room will automatically stop after 30-60 seconds. At this time, the staff can enter the clean room to conduct production experiments.

According to the different methods of air shower, there are currently two main classifications of air shower rooms in the market: single-sided air shower and double-sided air shower.

The double-sided air shower is equipped with nozzles on opposite sides. After entering the air shower, a person only needs to rotate 90 ° to be blown by high-speed tangential airflow throughout the body. The air shower with single-sided blowing only has a nozzle installed on one side. After entering the air shower, a person needs to rotate at least 270 ° to one side in order to be blown by high-speed tangential airflow throughout the body.

In addition, the air shower room will be divided into single, double, and multi person types. The author learned that many manufacturers in the market can also produce non-standard air shower rooms, but regardless of the form of air shower room, its structural principle is basically as described above. It should be noted that the doors of the air shower room need to be equipped with interlocking devices, which means that their doors cannot be opened simultaneously to ensure the cleanliness of the clean room is not contaminated. If there is no interlocking device, it will invisibly increase the training and management costs of the user.

Under what circumstances should an air shower be used? In a non unidirectional flow clean room, when the particles on the clean work clothes have a significant impact on the experimental production of the clean room, an air shower room must be used because it is difficult to achieve complete blowing solely through efficient air supply ports. In a unidirectional flow clean room, due to its high purification and blowing capacity, it is not necessary to set up an air shower room at this time, except for those with larger logistics equipment, which require a separate logistics air shower room. In addition, when using the air shower room, a bypass door is usually installed next to the air shower room for two main reasons. Firstly, it is for the use of staff after work, as air shower is generally not required for clean rooms; But it can facilitate escape and access to clean room related process equipment.

That’s all for the relevant knowledge about air shower rooms, hoping it will be helpful to you.

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

" width="300" height="300" alt="Modular cleanroom designs" />

" width="300" height="300" alt="Modular cleanroom designs" /> " width="300" height="300" alt="Classification Impacts For Cleanroom" />

" width="300" height="300" alt="Classification Impacts For Cleanroom" /> " width="300" height="300" alt="Modular Cleanrooms Facts" />

" width="300" height="300" alt="Modular Cleanrooms Facts" /> " width="300" height="300" alt="Cleanroom HVAC Designs" />

" width="300" height="300" alt="Cleanroom HVAC Designs" />

HelloPlease leave a message