Search the whole station

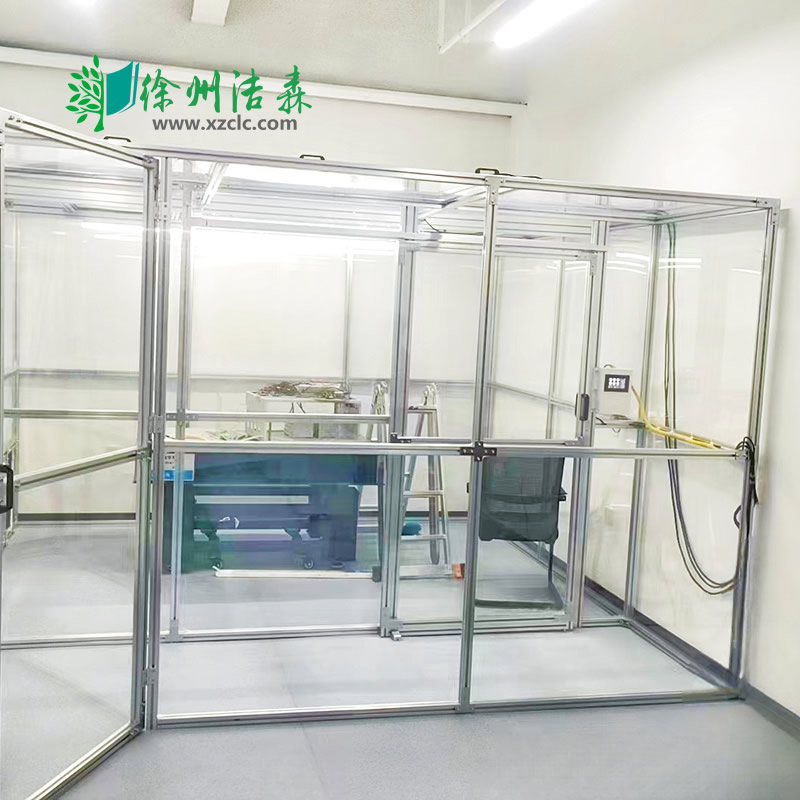

The tempered glass panel clean room (CLEAN BOOTH) is a simple clean room built for quick and convenient use. The tempered glass panel clean room has multiple cleanliness levels and space combinations that can be designed and manufactured according to usage needs. Therefore, its main characteristics are simple use, high elasticity, easy installation, short construction period, and portability. The clean room can also be locally added to areas that require high cleanliness in general grade clean rooms to reduce costs. Tempered glass panel clean room is an air purification equipment that can provide a locally high cleanliness environment. The tempered glass panel clean room is mainly composed of a box, a fan, a primary air filter, a damping layer, lighting fixtures, etc., and the outer shell is sprayed with plastic. This product can be hung or supported on the ground, with a compact structure and easy to use. It can be used individually or connected in multiple ways to form a belt shaped clean area.

The tempered glass panel clean room adopts industrial aluminum (or stainless steel square tube, iron square tube spray) as the frame, with fan filter unit (FFU) for air supply, and anti-static curtains (or tempered glass) hung around. Its internal purification level can reach 100-10000 levels. Suitable for areas with high local purification requirements within the operating zone.

Product preparation:

1. Framework: Industrial aluminum (or stainless steel square tube, iron square tube spray) is used as the frame to ensure stability, aesthetics, rust resistance, and dust-free properties;

2. Anti static curtains: Anti static curtains (or acrylic sheets) are used around the perimeter, which have good anti-static effect, high transparency, clear grid, good flexibility, no deformation, and are not easily aged;

3. Fan filter unit FFU: It adopts Singapore PCI centrifugal fan, which has the characteristics of long life, low noise, maintenance free, low vibration, and stepless speed change. The fan quality is reliable, the working life is long, and the unique air duct design greatly improves the efficiency of the fan and reduces noise! The internal purification level can reach 100-100K level; Especially suitable for areas with high local purification requirements in the workshop, such as assembly line operation areas.

4. The interior adopts a dedicated purification lamp for the purification room, which does not produce dust;

Product features:

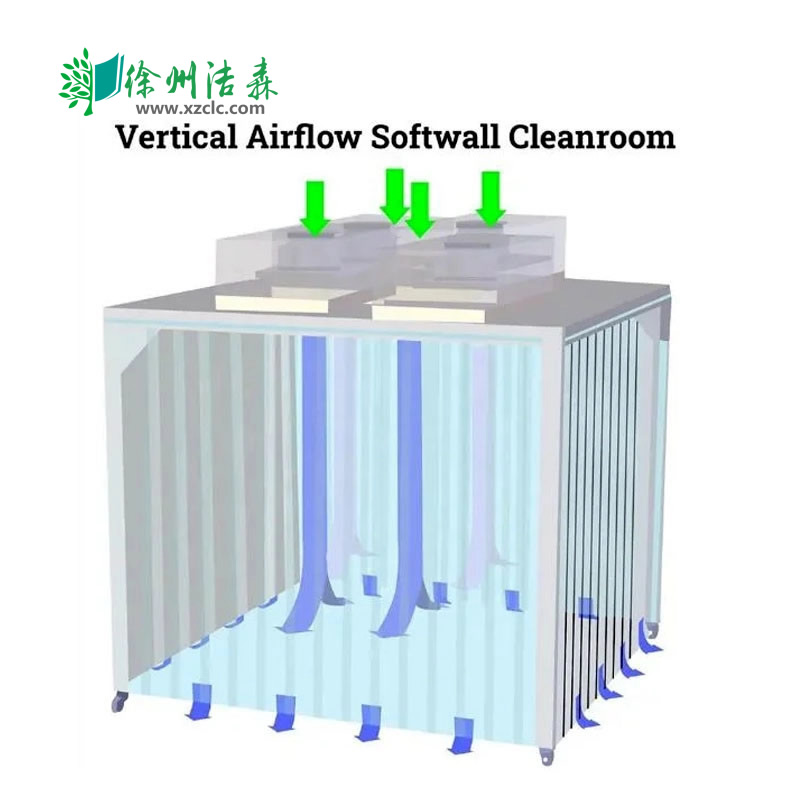

The cleanliness of tempered glass panel cleanrooms is often affected by airflow, in other words, the movement and diffusion of dust generated by people, machine compartments, building structures, etc. are dominated by airflow.

The cleanroom system uses HEPA and ULPA to filter air, with a dust collection rate of up to 99.97-99.99995%. Therefore, the air filtered through this filter can be said to be very clean. However, in addition to people, there are also sources of dust such as machines in the clean room. Once these generated dust particles spread, it is impossible to maintain a clean space. Therefore, it is necessary to use airflow to quickly remove the generated dust from the outside.

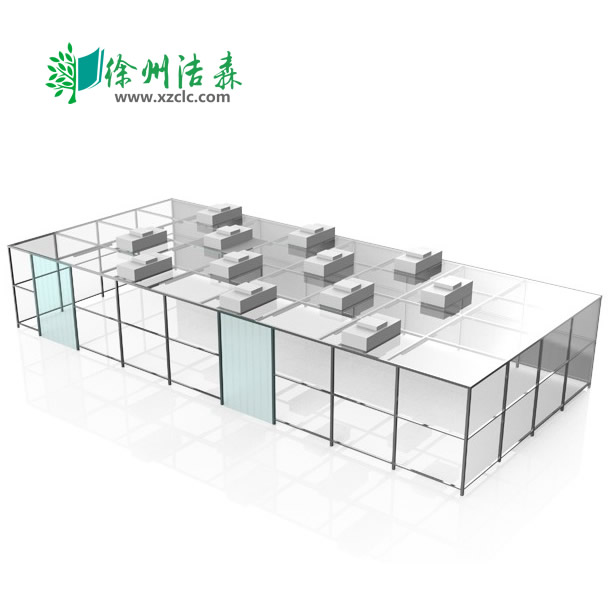

Tempered glass panel clean room is a simple clean room that can be quickly assembled. It has the characteristics of fast installation, short construction period, low price, and easy mobility. Controlling the main production processes in a smaller environment is also a choice for clean room design.

advantage:

1. It can be used alone or in combination.

Compared with civil or prefabricated cleanrooms, Class 100 cleanrooms have lower investment, faster results, easier installation, and lower operating costs.

3. Modular structure, easy to improve cleanliness level, strong scalability, and high reuse value

4. Easy to move (universal wheels can be installed)

*Note: This product accepts non-standard customization from customers.

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.