A clean room, also known as a simple clean room, is a temporary or mobile clean working environment with specific cleanliness requirements. The emergence of clean rooms aims to meet the needs of places or projects that require high cleanliness but do not require the establishment of permanent clean rooms. It is widely used in multiple industries such as electronics, semiconductors, pharmaceuticals, and food due to its flexibility, economy, and efficiency.

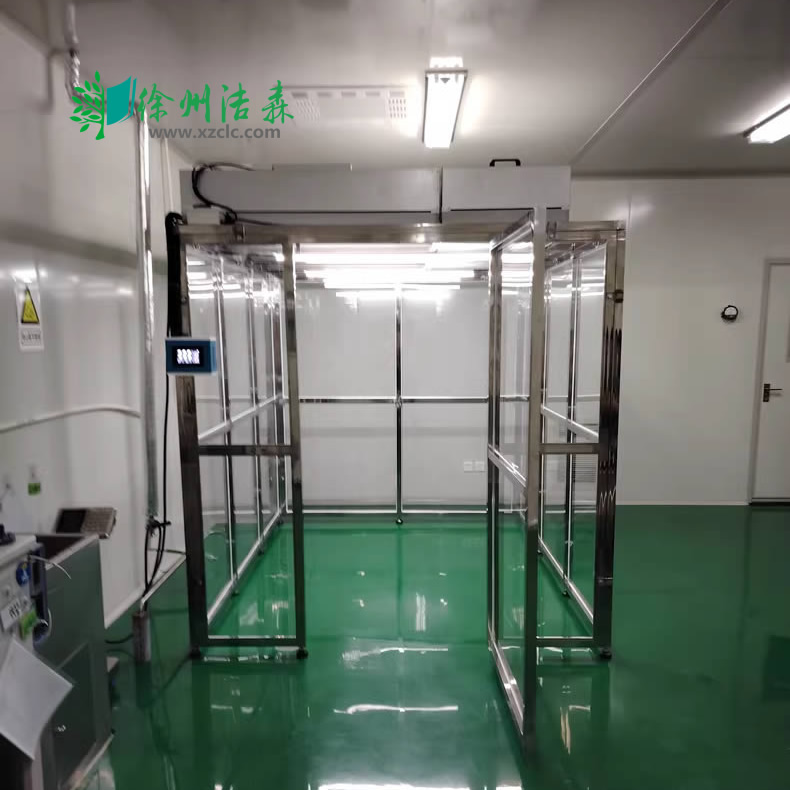

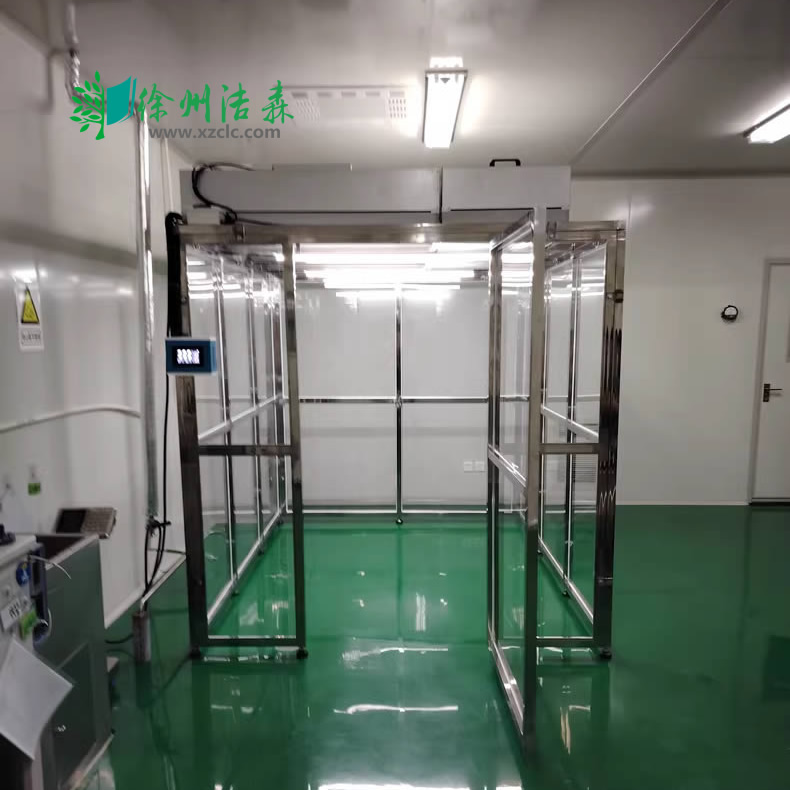

The structural design of a clean room usually includes several parts, such as the top structure, surrounding structures, bottom structure, and internal air purification system. The top structure is generally light steel keel frame, matched with anti-aging square aluminum beam, which is beautiful in appearance and stable and durable. The surrounding enclosure structure uses anti-aging industrial reinforced sandwich color steel plate, which is not only beautiful, but also can effectively isolate the impact of the external environment on the inside of the clean shed. The bottom structure can be selected according to actual needs, such as anti-static flooring, elevated flooring, or cement flooring.

The internal air purification system is the core part of the cleanroom, mainly including high-efficiency air filters, supply air systems, return air systems, etc. Efficient air filters can remove pollutants such as particles, bacteria, viruses, etc. from the air, ensuring the air quality inside the clean room. The air supply system sends filtered clean air into the cleanroom to maintain its cleanliness. The return air system extracts the air inside the clean room, processes it, and sends it back in to form a cycle.

The cleanliness level of a cleanroom is generally classified according to the standard ISO 14644-1, with common levels including ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, etc. Different levels of clean rooms have different requirements in terms of structure, materials, air purification systems, etc., to meet the production or research and development needs of different industries.

The establishment and use of clean rooms require adherence to certain standards and operating procedures. For example, before entering the clean room, personnel need to undergo strict cleaning treatment, including changing clean clothes, wearing clean hats, clean shoes, etc. At the same time, regular cleaning, disinfection, testing, and other operations need to be carried out inside the cleanroom to ensure that its cleanliness remains within the required range.

The application range of clean rooms is very wide, especially in industries that require extremely high cleanliness. In the electronics industry, cleanrooms are used to produce high-precision products such as integrated circuits and semiconductors; In the pharmaceutical industry, clean rooms are used for the research and production of drugs, biological products, etc; In the food industry, clean rooms are used for producing high-end food, health products, etc. In addition, clean rooms are widely used in fields such as scientific research, teaching, and experimentation.

Overall, as a simple clean room, the cleanroom provides a convenient and reliable clean working environment for many industries due to its flexibility, economy, and efficiency. With the continuous advancement of technology and the increasing demand for cleanliness, the application prospects of clean rooms will be even broader.

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

" width="300" height="300" alt="Modular cleanroom designs" />

" width="300" height="300" alt="Modular cleanroom designs" /> " width="300" height="300" alt="Classification Impacts For Cleanroom" />

" width="300" height="300" alt="Classification Impacts For Cleanroom" /> " width="300" height="300" alt="Modular Cleanrooms Facts" />

" width="300" height="300" alt="Modular Cleanrooms Facts" /> " width="300" height="300" alt="Cleanroom HVAC Designs" />

" width="300" height="300" alt="Cleanroom HVAC Designs" />

HelloPlease leave a message