What is a clean room? Application and principle of clean room

What is a clean room?

A cleanroom is a space cleaning system that maintains positive pressure in a simple space to prevent dirt from entering from the outside.

Unlike cleanrooms that require strict management, cleanrooms are used for occasions that require localized and simple space cleaning environments.

Purpose of using a clean room

Clean rooms remove dust and other particles from the air at a microscopic level, while controlling temperature and humidity within a certain range. These performances have been standardized by ISO and JIS, making it an extremely advanced space cleaning system.

On the other hand, when there is no need to control the cleanliness of a large workspace and a certain degree of local cleanliness is required, a clean room is used. For example, they are used in semiconductor manufacturing plants, LCD panel manufacturing plants, pharmaceutical manufacturing plants, cosmetics manufacturing plants, and food manufacturing plants.

In addition, when it is necessary to further improve the clean environment of the space, the cleanroom can be used in conjunction with the cleanroom.

Clean room principle

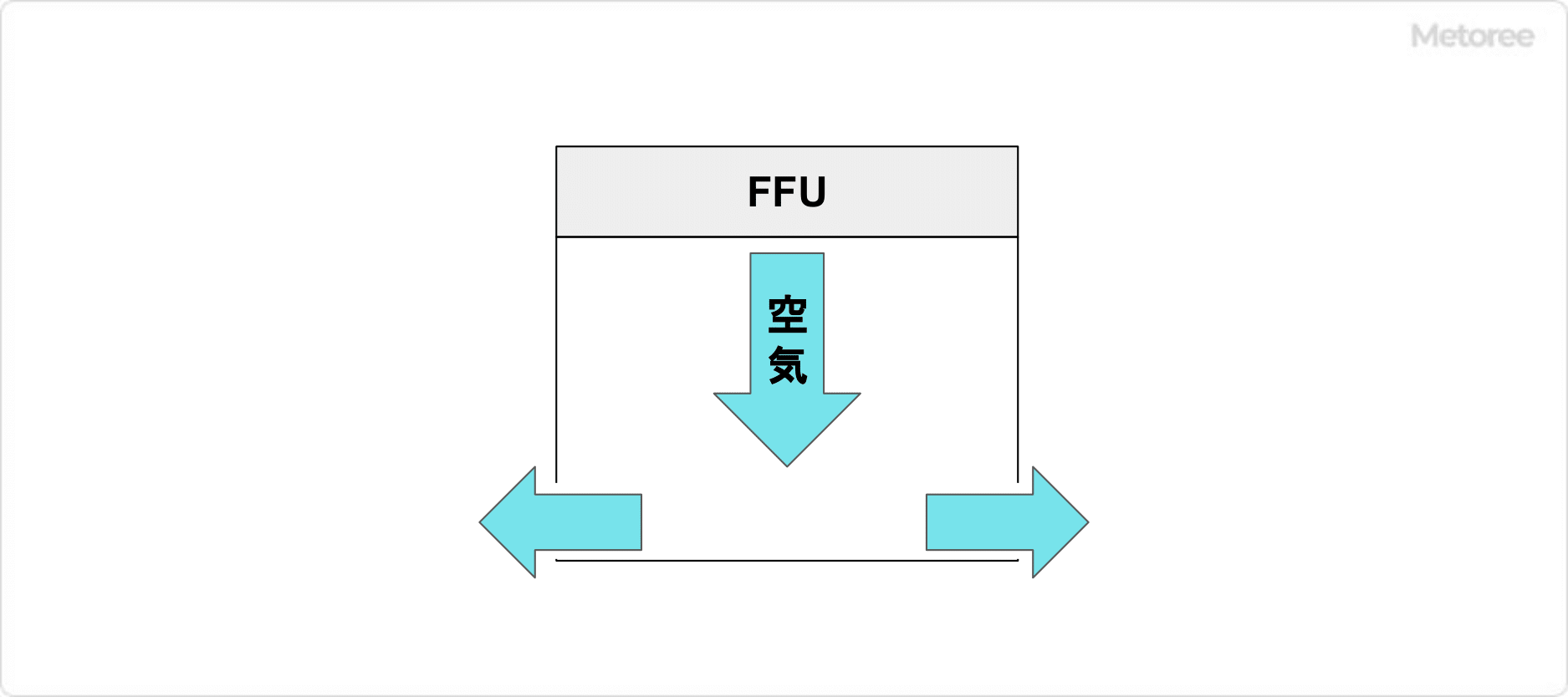

What is a clean room? Application and principle of clean room

Figure 1 Principle of Cleanroom

A typical clean room uses insulation panels and air conditioning to control humidity and temperature, as well as cleaning equipment such as positive pressure devices and differential pressure dampers to set room pressure to strictly maintain a clean environment.

On the other hand, in a typical clean room, the small space composed of frames and other components is covered with PVC sheets to isolate it from the external space, and a fan filter unit (FFU in the UK) is installed on the ceiling of the clean booth to keep the environment clean. FFU maintains positive pressure inside the cleanroom to prevent dust from entering from the outside. It is most important to choose an FFU that can generate positive pressure in the indoor space based on the size of the cleanroom.

Instructions for using a clean room

When using a clean room, the following points should be noted.

Measures must be taken to prevent dirt, dust, and microorganisms from entering the clean room. Relying solely on the performance of the clean room is dangerous, so it is necessary to determine the usage rules and procedures in advance and raise the awareness of the users themselves.

Cleaning FFU is also important. Especially, if the air intake is not cleaned properly, the cleanliness inside the booth will deteriorate, so it is necessary to establish a regular cleaning procedure.

A clean room is a simple system with gaps at the bottom. The internal control of the cleanroom is positive pressure, but insects and other insects can enter, so the floor around the cleanroom must always be kept clean.

The frequency and method of cleaning, as well as the frequency of filter replacement, will vary depending on the level of cleanliness you require. You need to consider in advance what kind of management is needed based on the conditions of the usage environment.

Types of Cleanrooms

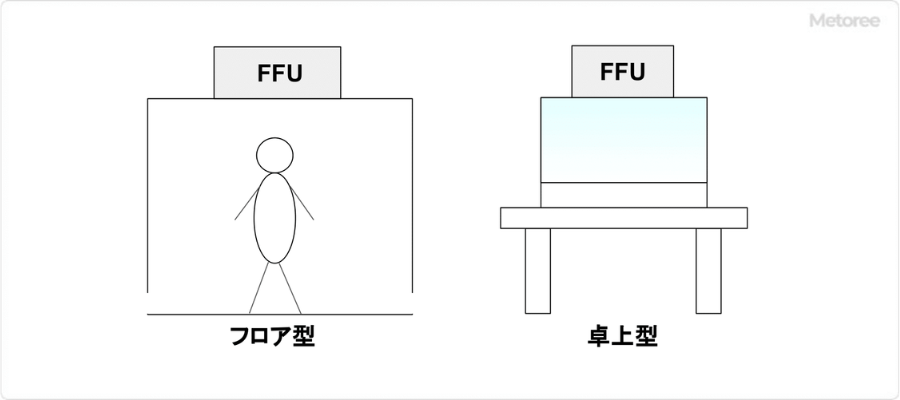

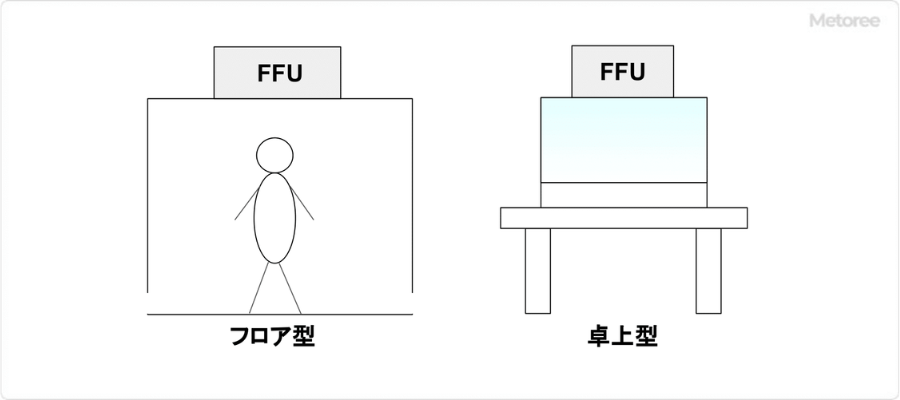

1. Floor standing and desktop style

What is a clean room? Application and principle of clean room

Figure 2 Floor standing and desktop clean rooms

Floor standing is a large clean room installed on the floor where people enter and exit. Used during large-scale work. Generally, personnel entering the clean room must wear clean clothing to prevent foreign objects from entering the clean room. Floor standing clean sheds are mainly used in production sites such as factories.

Desktop cleanroom is a small cleanroom installed on a table. In general, workers only need to place their hands in the clean room and can easily use it without wearing clean clothes. Desktop cleanrooms are smaller and more compact than other types of cleanrooms, making them suitable for use in limited spaces in laboratories and factories. They are usually easy to install and maintain, and have relatively low costs, so they are used by many companies and research institutions.

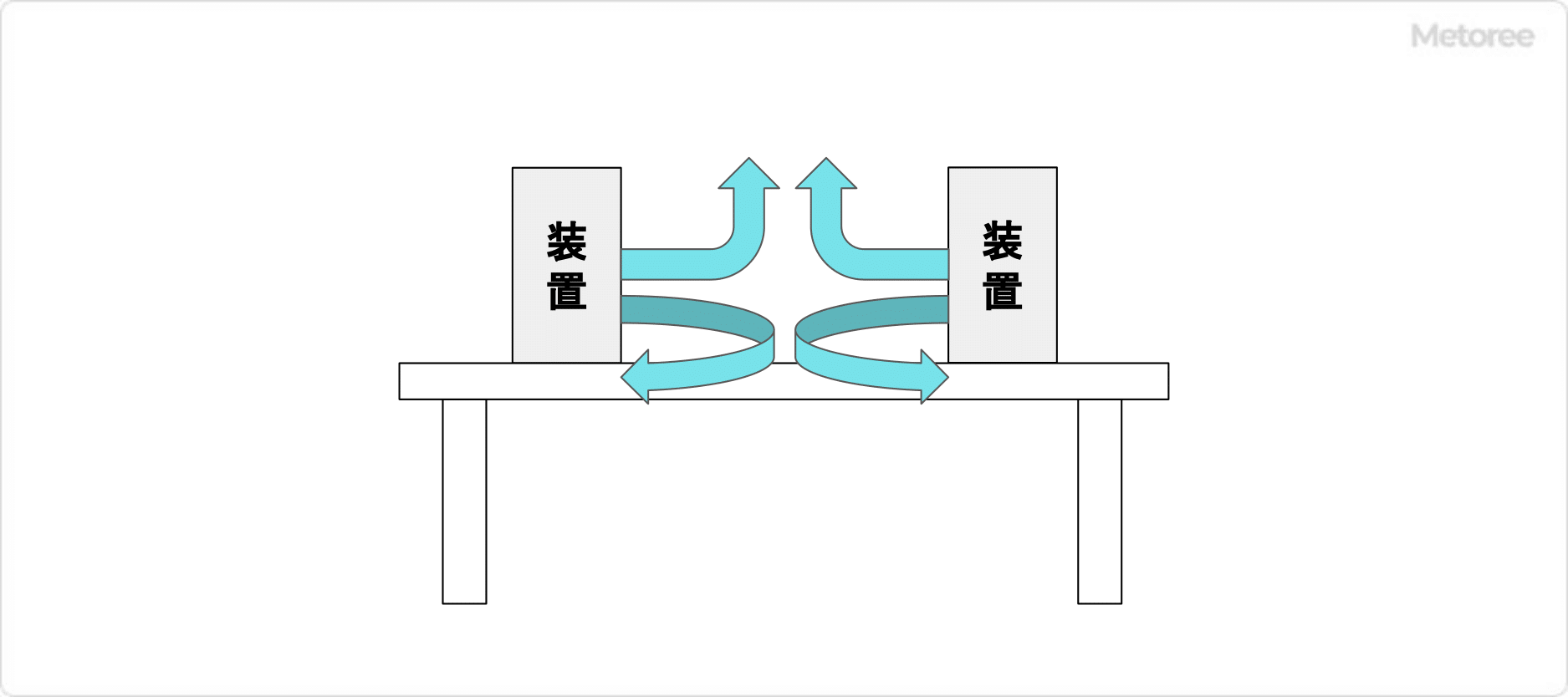

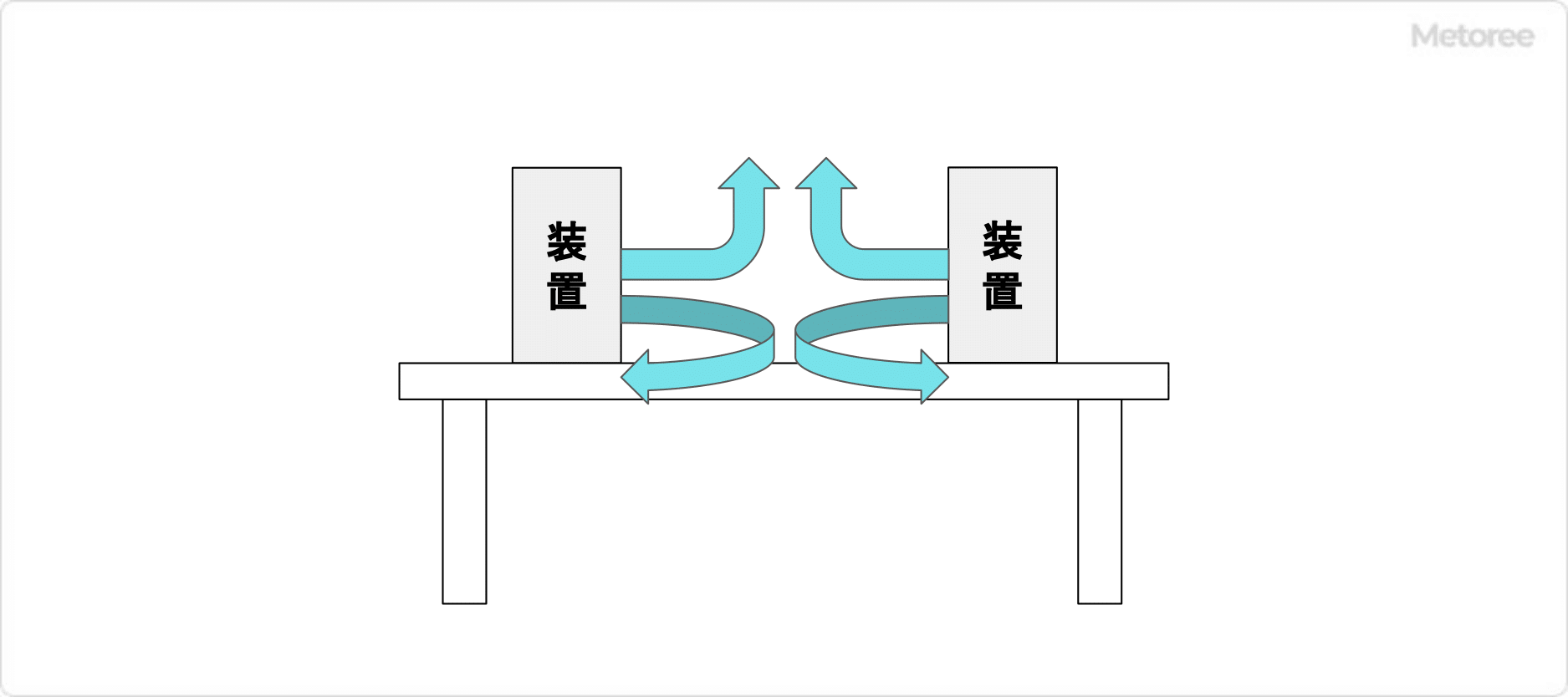

2. Closed and open

What is a clean room? Application and principle of clean room

Figure 3 Open cleanroom

Closed cleanrooms that form sealed spaces are mainstream, but there are also open ones. An open cleanroom is a device that continuously generates clean air flow between a pair of air supply devices and operates within the space. It is easier to carry than a closed cleanroom and can be used when you want to keep your local workspace in a level 1 highly clean environment.

3. Standard and customized models

Cleanroom manufacturers not only sell standard sizes and specifications of cleanrooms, but also accept customization from users. Due to the fixed size of the standard model, it can be obtained at a lower price than the customized model. Custom types can be made to any size you want, and various options can be added, such as connecting FFU anemometers.

Other information about the clean room

1. Cleanroom curtains

The curtains of the clean room have various characteristics and should be selected according to the conditions of the usage environment.

The functions of curtains include flame retardancy, insect resistance, anti-static, thermal insulation, and shading. When static electricity is generated, it creates an environment that is prone to dirt and dust, so curtains with anti-static properties are effective.

2. Aluminum frame clean room

Some clean rooms use aluminum frames. The advantages of using aluminum frames include:

light

Aluminum is a very light metal, with a specific gravity of about 2.7 for aluminum and about 7.8 for iron. The weight of aluminum is about one-third that of steel.

The surface of aluminum frames is usually treated with anodizing, which can reduce manufacturing costs and time. It can reduce processes such as electroplating and painting, thereby saving costs and time.

Easy to change design

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

Clean room,clean booth,Simple Purification shed manufacturer from China Jiesen

" width="300" height="300" alt="Modular cleanroom designs" />

" width="300" height="300" alt="Modular cleanroom designs" /> " width="300" height="300" alt="Classification Impacts For Cleanroom" />

" width="300" height="300" alt="Classification Impacts For Cleanroom" /> " width="300" height="300" alt="Modular Cleanrooms Facts" />

" width="300" height="300" alt="Modular Cleanrooms Facts" /> " width="300" height="300" alt="Cleanroom HVAC Designs" />

" width="300" height="300" alt="Cleanroom HVAC Designs" />

HelloPlease leave a message