Search the whole station

|

Product Name:

|

Negative Pressure Laminar Air Flow Hood

|

Purification Levels:

|

Class 100

|

|

Specification:

|

Customize

|

Flow Type::

|

Vertical Laminar Flow

|

|

Usage:

|

Use Alone Or In Combination

|

Packaging:

|

Wooden Case

|

|

Terms:

|

CIF/EXW/FOB

|

According to the GMP (1998 revision) requirements, the current general pharmaceutical manufacturing plant is divided into 300,000, 100,000, 10,000, and 100, depending on the type of production. A clean grade, the 100th grade is the highest cleanliness level.

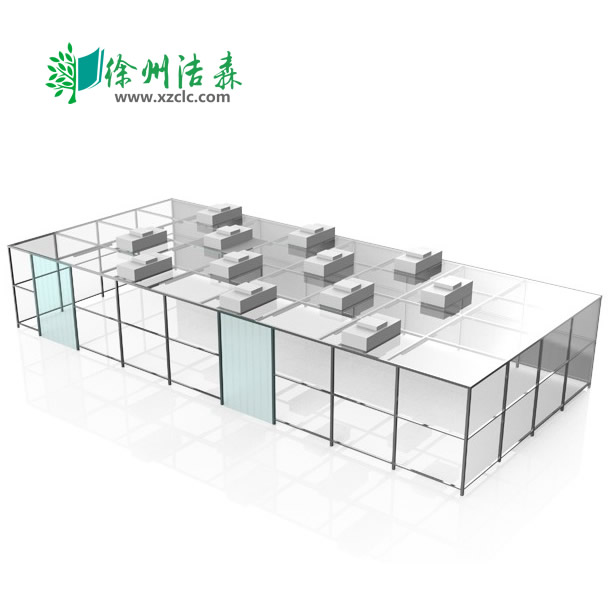

In a dust-free workshop of a pharmaceutical production plant, there will often be local 100-level areas, or require a certain room or several rooms to be class 100, or require certain areas in a room to be class 100. These 100 class areas are generally not large. , ranging from tens of square meters to a few square meters and even a fraction of square meters, is usually part of a process assembly line within a clean room. The Class 100 area is generally located in the inner area of the workshop, surrounded by 10,000 class or 100,000 class areas. The Class 100 area is part of the assembly line of the workshop. The entire assembly line also includes Class 10,000 or class 100,000. The 100-level area is generally lower in floor height (≤2.8m) and the environment is closed. It requires high noise and requires ≤65dB.

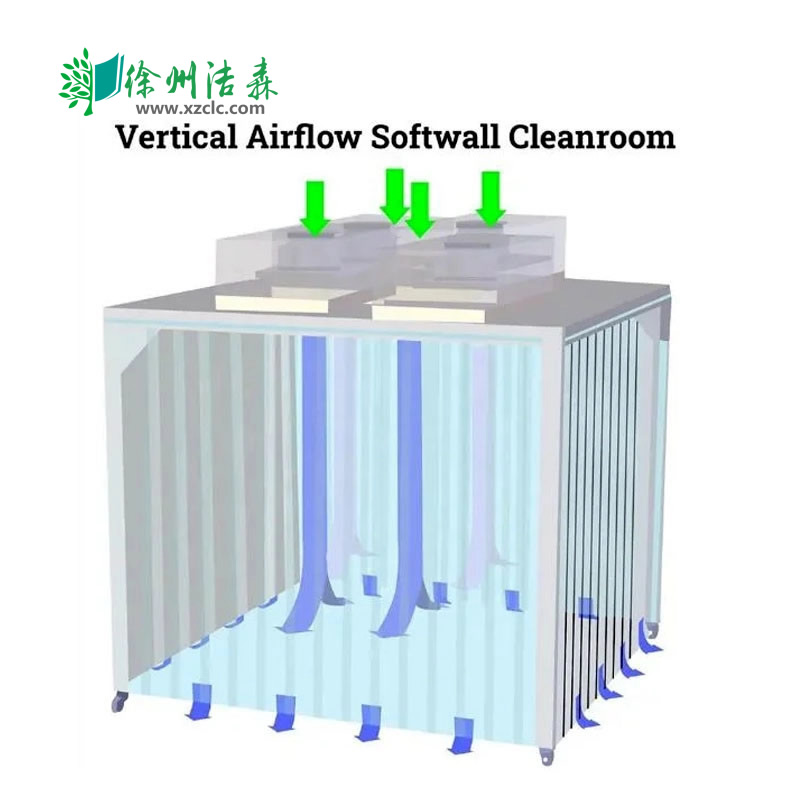

1). Purpose: The clean laminar flow hood is an air purification unit that can provide a local high clean environment and can be flexibly installed above the process requiring high cleanliness. Clean laminar flow hoods can be used individually or as multiple strips of clean areas. The device is a unidirectional flow purification device with top, side or bottom air inlet and bottom air supply, which can be widely used in electronics, pharmaceuticals, precision instruments, scientific research and other fields.

2). Principle: The clean laminar flow hood blows the pre-filtered air into the static pressure box with a certain wind speed, and then the hepa filter equalizes the pressure of the damping layer, so that the clean air flows vertically into the working area. , thus ensuring the cleanliness of the work area to achieve the process requirements.

3). Structure: There are three kinds of clean laminar flow hood with fan installed, fan installed above and fan installed. Mounting methods are suspended, floor stand and mobile. The structure can be divided into wall plate type, full iron shell paint, stainless steel outer shell iron and stainless steel and other forms.

| Model/parameter | Class Ⅰ | Class Ⅱ | Class Ⅲ |

| Efficiency | 99.99% | ||

| The wind speed(m/s) | 0.45 | 0.3 | 0.23 |

| Air supply size (mm) | 2600×2400 | 2600×1800 | 2600×1400 |

| Boundary dimension (mm) | 2680×2480×500 | 2680×1880×500 | 2680×1480×500 |

| Hepa size and QTY | 610*305*292mm 8pcs | 610*305*292mm 6pcs | 610*305*292mm 4pcs |

| Usage occasion | Class Ⅰ Special clean operating room. | Class ⅡStandard clean operating room. | Class Ⅲ General clean operating room. |

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

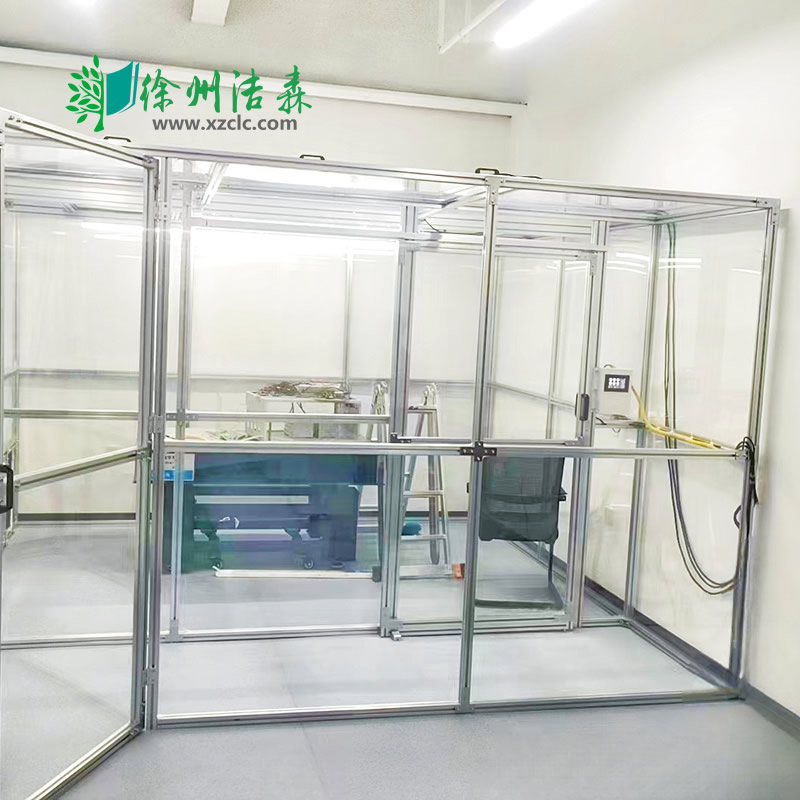

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.