Search the whole station

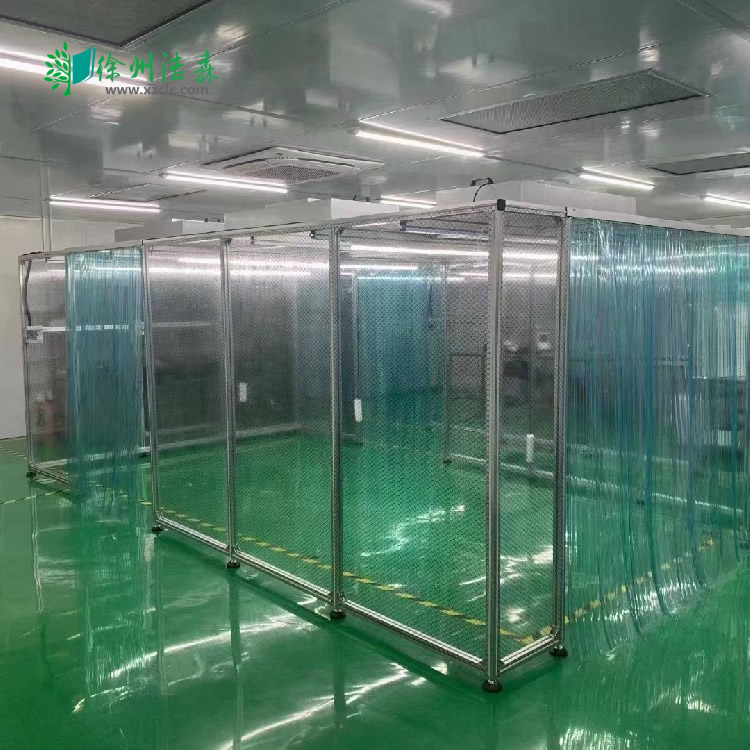

Clean Work Shed | Clean Shed is a product developed and produced by Xuzhou Jiesen that is easy to install, has high cleanliness, and can be reused, intersecting with the bottom of the cost of clean rooms!

Advantages of Clean Work Shed | Purification Shed:

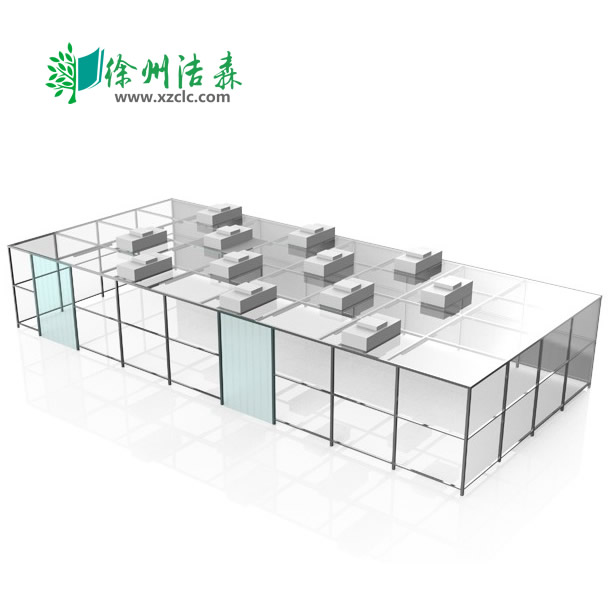

1. It can be used alone or in combination.

2. Compared with civil or prefabricated Class 100 cleanrooms, it has lower investment, faster results, easier installation, and lower operating costs.

3. Modular structure, easy to improve cleanliness level, strong scalability, and high reuse value.

Clean working shed | Main technical parameters of purification shed:

1. Purification level: 100 to 300000 levels (US Federal Standard 209E)

2. Average wind speed: 0.25-0.45m/s (adjustable)

3. Noise: ≤ 58dB (A)

4. Power supply: 220V 50HZ

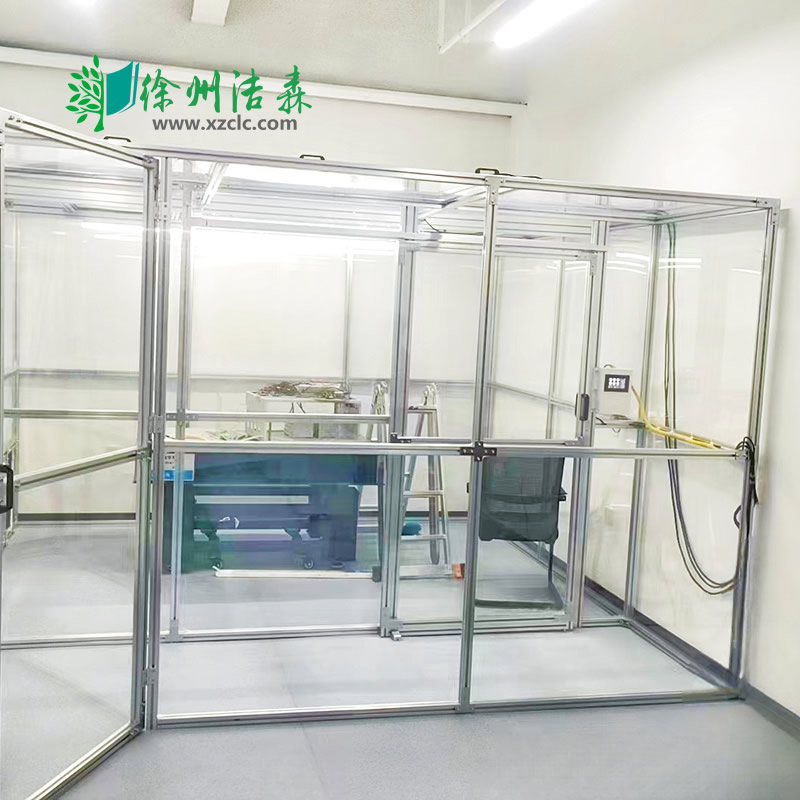

5. Frame: Industrial aluminum (or stainless steel square tube, iron square tube spray) is used as the frame to ensure stability, beauty, non rusting, and dust-free;

6. Anti static curtains: Anti static curtains (or tempered glass) are used around the perimeter, which have good anti-static effect, high transparency, clear grid, good flexibility, no deformation, and are not easily aged;

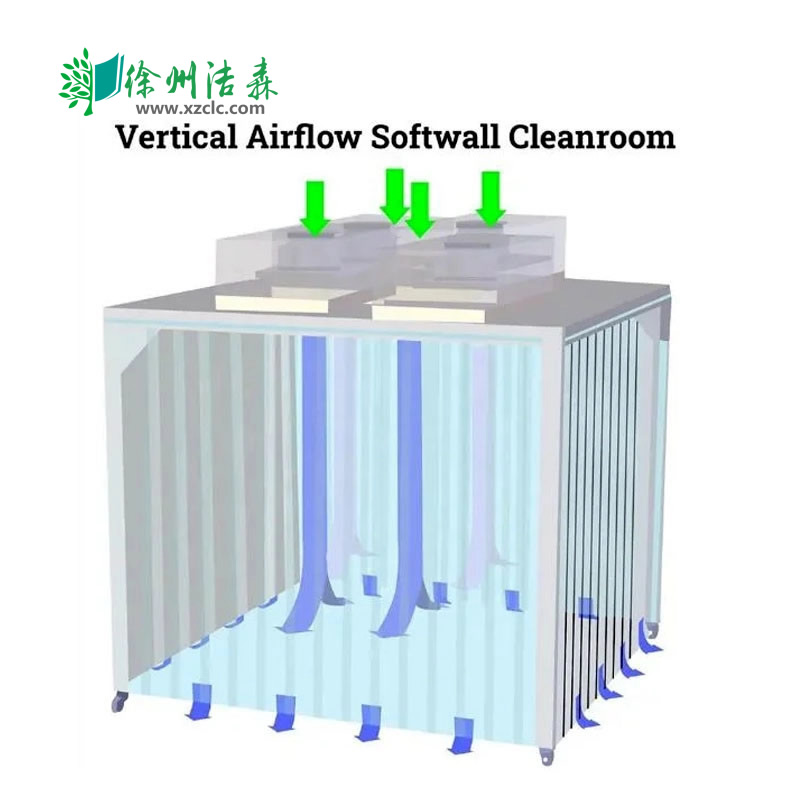

7. FFU fan filtration unit: using a centrifugal fan, it has the characteristics of long life, low noise, maintenance free, low vibration, and stepless variable speed. The fan is reliable in quality and has a long working life. Coupled with a unique air duct design, it greatly improves the efficiency of the fan and reduces noise! The internal purification level can reach 100-100K level; Especially suitable for areas with high local purification requirements in the workshop, such as assembly line operation areas.

Clean working shed | Purpose of purification shed:

CLEAN BOOTH, also known as a purification shed, is a simple clean room that can be quickly and conveniently built. The purification shed has multiple cleanliness levels and space combinations that can be designed and manufactured according to usage needs. Therefore, its main characteristics are simple use, high flexibility, easy installation, short construction period, and portability. The clean shed can also be locally added to areas that require high cleanliness in general grade clean rooms to reduce costs. A clean room is an air purification device that can provide a locally high cleanliness environment. The clean room is mainly composed of a box, a fan, a primary air filter, a high-efficiency air filter, damping layer lamps, etc., and the outer shell is sprayed with plastic. This product can be hung or supported on the ground, with a compact structure and easy to use. It can be used individually or connected in multiple ways to form a belt shaped clean area.

The main materials of a clean room directly affect its cleanliness and effectiveness. So, what are the main materials of a clean room? We all know that a clean room is a simple clean room built for the fastest and most convenient use. The clean room has multiple cleanliness levels and space combinations that can be designed and manufactured according to usage needs. Therefore, its main characteristics are simple use, high flexibility, easy installation, short construction period, and portability.

The main materials for the clean work shed and purification shed are as follows:

A. The brackets around the clean room are made of industrial aluminum profiles, stainless steel square pipes, or iron square pipes with multi-layer acid washing and electrostatic spraying as the frame, which is corrosion-resistant, rust proof, and aesthetically pleasing. The commonly used plates for clean rooms include cold-rolled steel plates (A3 plates) and stainless steel plates (SUS201, SUS304, SUS316, etc.), with a thickness generally ranging from 0.8 to 1.5mm. Different materials and size configurations directly affect the price and cost of clean rooms.

B. The cleanroom can be equipped with hanging curtains or glass around it, and different materials may result in different prices and costs for the cleanroom.

C. Clean room principle: The FFU fan filtration unit sucks in fresh air through the primary filter for the first filtration, and then passes through the high-efficiency filter for the second filtration 99.99@0.3um After filtration, the entire air outlet surface is uniformly sent out into the clean room at a speed of 0.45m/s ± 20%, ensuring a vertical unidirectional flow of clean air and maintaining the required cleanliness in the work area.

Clean working shed | One stop service for design and construction of purification shed.

Highlight: clean room booth oem, clean room booth class 100, clean booth class 100 Temperatur……

Highlight: industrial grade clean room booth, contamination control clean room booth, air distribu……

Highlight: ISO6 Soft Curtain, Anti-static Soft Curtain, Clean Room Soft Curtain Product Name: ……

The (SS-MAC) is an affordable and adaptive Clean room unit. It is packaged as a DIY (do-it-yoursel……

Laminar Flow Clean Booth provides a sterile working environment. The Laminar Flow Booth is continu……

Clean booths are used for either localized or advanced particle cleaning to achieve cleanroom stan……

Product Introduction A clean room is a simple purification device with low investment, high purifi……

A hardwall cleanroom for medical device manufacturing requires precision at every intersection, ……

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.